Every capsule we buy contains a precise dose of medication. So, have you ever wondered how this is done? The secret lies in the capsule filling machine.

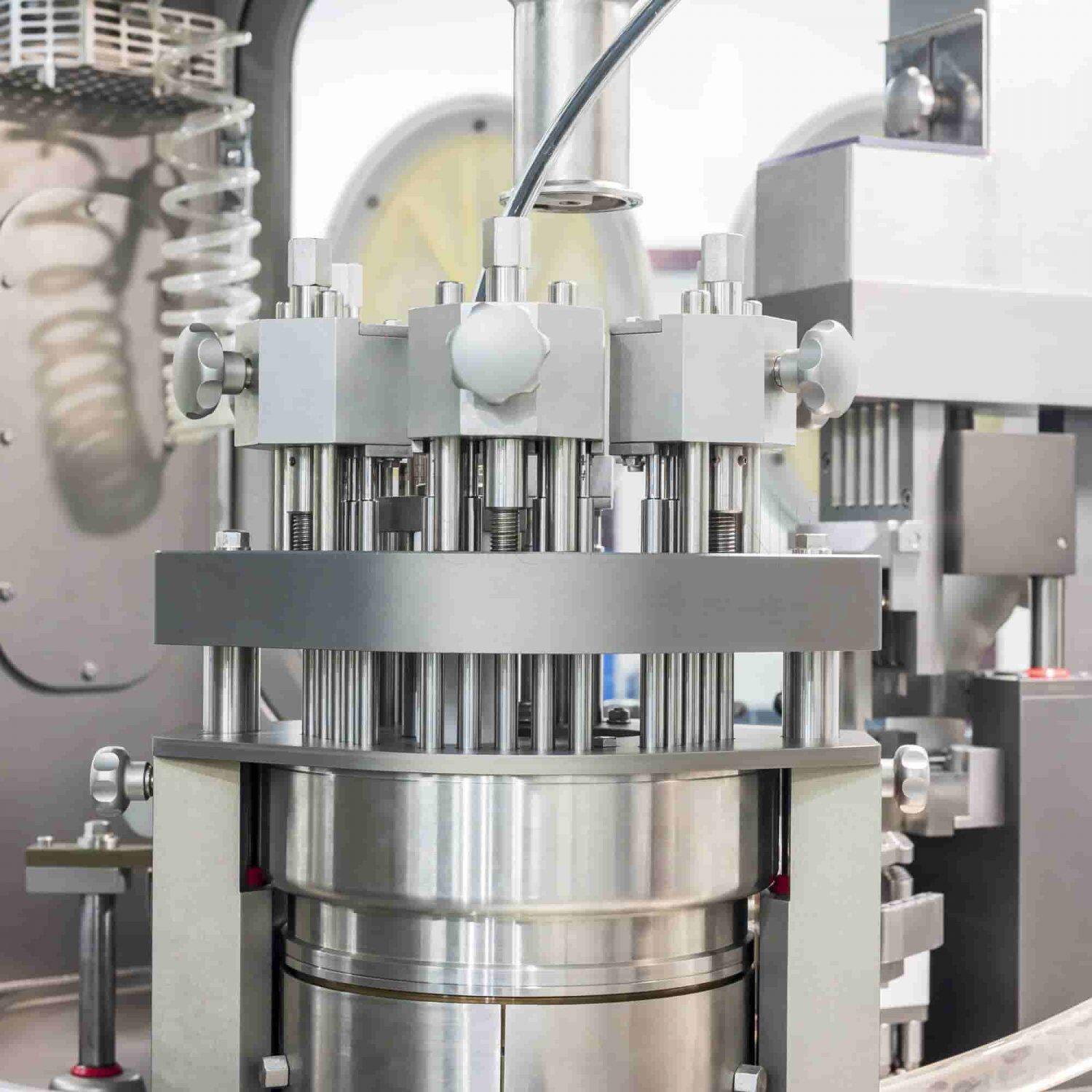

A capsule filling machine is not a simple machine. It consists of many parts, each working together for efficient operation. It is this interplay that allows the raw material to be transformed into precisely measured capsules.

So, let's find out what these amazing capsule filling machine parts are.

Top 9 Key Parts of a Capsule Filling Machine

1. Capsule Hopper

The capsule hopper is primarily the " feeding chute " of the capsule filling machine. This hopper typically uses food-grade stainless steel for durability and hygiene. Depending on the capacity of the machine, the capsule hopper can come in a variety of shapes, such as cylindrical, conical or cubic.

Beyond storing the capsules, the hopper also feeds the capsules into the filling machine using a controlled vibration system. This helps to stabilize the flow of capsules while maintaining precise positioning and separation for correct filling.

2. Capsule Feeding System

Imagine thousands of capsules piled messily in a hopper. How can you pick out only one capsule that is oriented exactly the same way for filling? A capsule feeding system can help. It precisely separates each capsule and keeps it upright and ready for filling. It may seem like a small job, but one irregular capsule can cause a lot of problems for the entire production line.

3. Powder Hopper

Next is the powder hopper. You can think of it as the machine's storeroom. It stores the powders, pellets, or other things that will go into the capsules. But it's more than just a simple container! The hopper utilizes a clever mechanism, such as gravity or a rotating screw, to keep this material flowing to the next station. This ensures that you always have enough material on hand for precise filling.

4. Powder Dosing & Filling System

We all know that the powder dosing filling system is the core of the capsule filling machine. So what is its main job? That is to measure and fill the exact amount of powder for each capsule. But there is no magic one-size-fits-all solution here. Different powders behave differently, so you need to use different dosing mechanisms to ensure maximum accuracy. Here are two of the most common methods:

Dosator-- This method uses a piston or screw to draw and measure a specific amount of powder from a hopper. The measured dose is then ejected into the capsule. Dosator is highly accurate and suitable for a wider range of powder types, including poorly flowing powders.

Dosing Disc-- This method uses a rotating disk with multiple cavities. As the disk rotates, the tamping pin pushes the powder from the hopper into the cavities. Once filled, the disk rotates further and the tamping pin compacts the powder. Finally, the compressed powder is ejected into the capsule. The dosing disc may not be suitable for all types of powders, especially less fluid powders. Also, it may not be as accurate as the dosator.

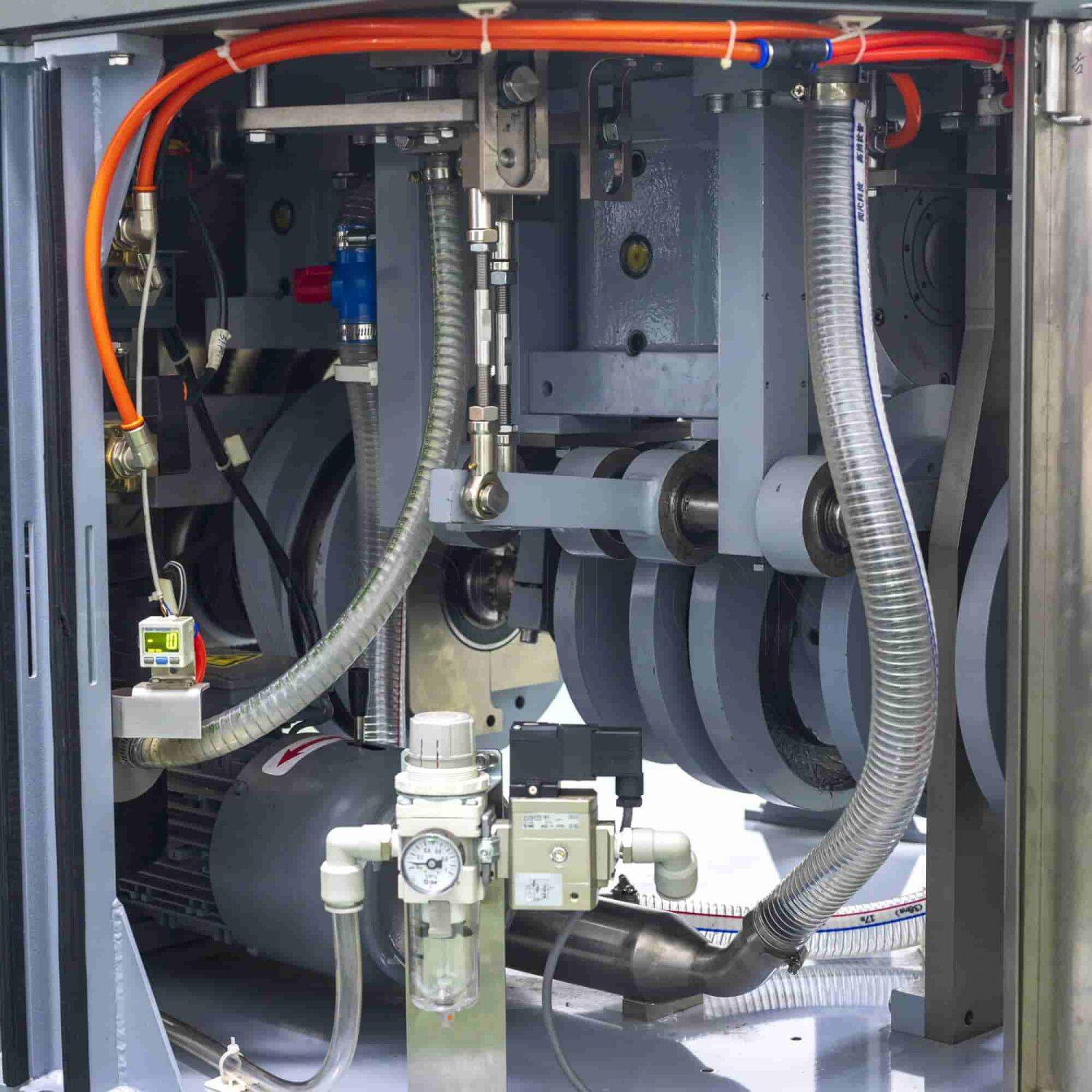

5. Lubrication System

In a capsule filling machine, the powder dosing system and capsule feeding unit take center stage, but there is another key part that works tirelessly behind the scenes, that is the lubrication system. As the machine operates, various parts move and rub against each other. Without proper lubrication, friction can cause these parts to wear out early, which may lead to potential machine breakdown. The lubrication system oils these parts and reduces friction. This will in turn extend the life of the machine.

6. Vacuum System

One of the main functions of a vacuum system is capsule separation. Capsules are usually stored in a large hopper and tend to get mixed up. Vacuum systems utilize low pressure to gently separate individual capsules from the bulk supply. This allows the capsules to enter the filling station precisely one by one.

In addition, the vacuum unit cleans the capsule zone after each filling cycle. This quick cleaning with no manual intervention eliminates any leftover powder or debris and ensures a clean and consistent filling process for the next capsule.

7. Motor

In a capsule filling machine, the motor is like the engine of a car. It is the main power source that keeps everything running. It takes electrical energy and converts it into the power needed to run the various parts of the machine.

Think of it this way, the parts of a capsule filling machine are like individual tools. The motor provides energy for the operation of these tools and further ensures smooth filling of the capsules.

8. Safety Door

The safety door is mainly designed to protect the operator. When your capsule filler is running, the parts inside will move very fast. If the operator accidentally puts his hand into the machine at this time, he could be seriously injured. This is why we need a safety gate in the capsule filler. It serves as a physical barrier to prevent the operator from putting himself in danger.

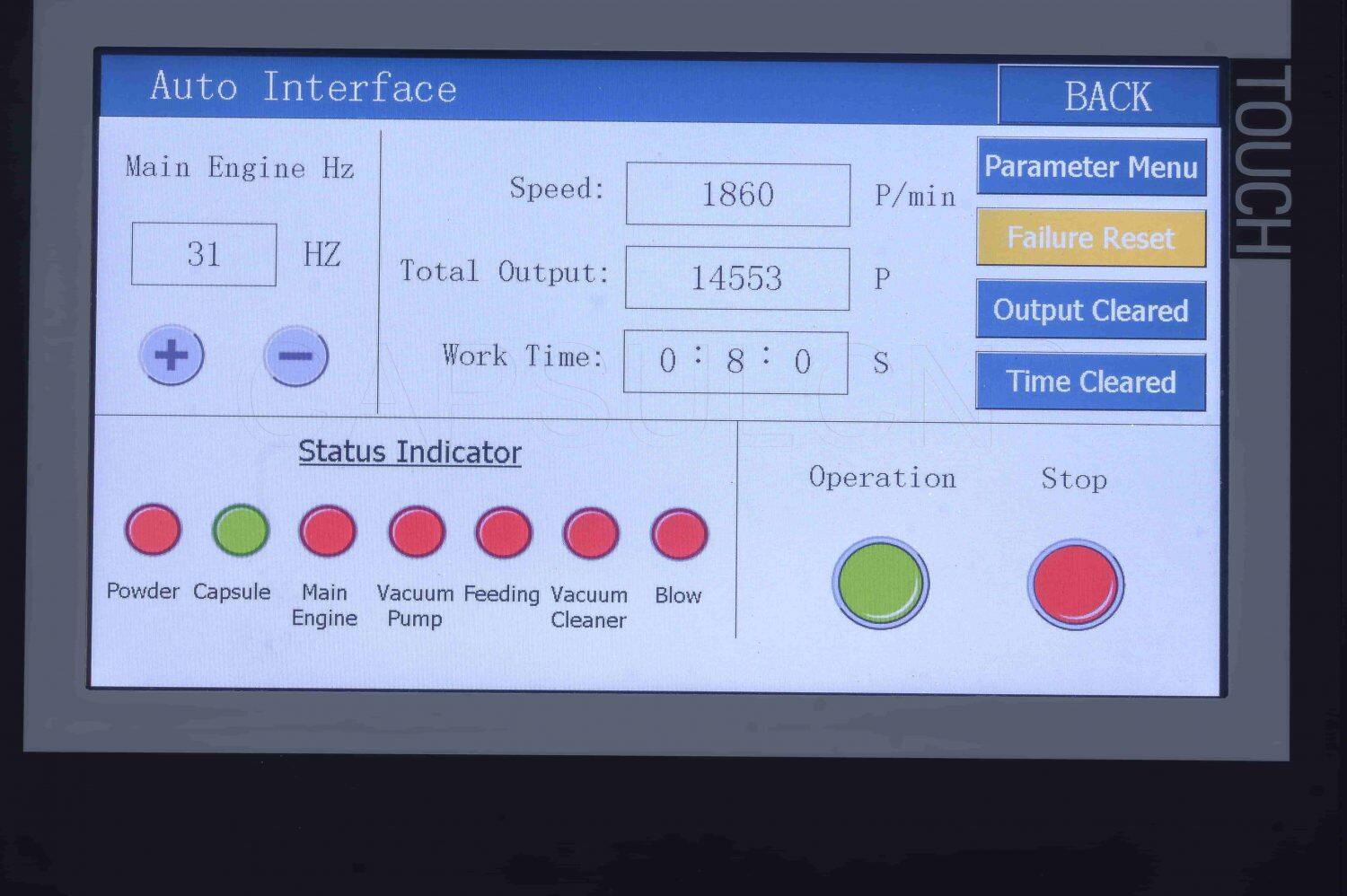

9. Control System

The control system of a capsule filling machine usually has two parts, the PLC and the HMI.

PLC (Programmable Logic Controller) is a specialized computer with a set of pre-programmed instructions. These instructions tell each part of the capsule filler what to do and when to do it. For example, it tells the dosing system how much powder to deliver, when the feeding unit releases the capsules, and when the safety gate locks.

HMI (Human Machine Interface) is usually a touch screen or control panel. It allows the operator to monitor the machine's operation in real time. In addition, the operator can use it to adjust certain parameters within a predefined range, such as raising or lowering the filling speed, changing the dosage, etc.

How to Keep Your Capsule Filling Machine in Top Shape?

Understanding the parts of your capsule filler is the first step. But the real mystery lies in how well these parts work together. Cleaning and maintenance! These practices are the secret to making sure your machine stays in tip-top shape for a long time. So let's explore how to effectively clean and maintain your capsule filling machine.

How to Clean Your Capsule Filling Machine?

For residual dust in places such as capsule filler hoppers and channels, you can use compressed air to clean them. For stubborn residue? This time you can choose a special cleaning solution according to the capsules and drugs to be filled, and then gently wipe with a soft cloth.

How Often Should I Clean My Capsule Filler?

The truth is, it depends on what and how much you produce. The rule of thumb is to perform a daily cleaning after each machine run and a deep cleaning at regular intervals.

How to Maintain Your Capsule Filler?

Remember to inspect the capsule filler regularly, such as checking for worn seals or loose parts. You will also need to lubricate and replace parts regularly according to the manufacturer's instructions. This will keep everything running smoothly and prevent your machine from breaking down in the future.