The importance of a capsule filling machine in producing medical capsules cannot be overstated, especially if you’re looking to scale your pharmaceutical business. A capsule filling machine enhances the production, packaging, and distribution of capsulated medications, whether in powder, pellets, granules, etc.

HUADA Pharma is one of the leading producers of pharmaceutical equipment worldwide. We understand the importance of having state-of-the-art tools that enhance and expedite the production of essential medications.

We have outlined the major types of capsule filling machines available in the industry. We also explain which suits your business, whether you’re a large or small pharmaceutical company. You will also learn about their features and functionalities and where to get them should you find one suitable for your business.

What is a Capsule Filling Machine?

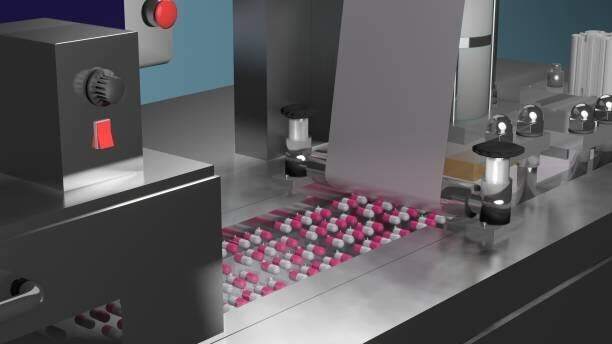

Industrially called capsule fillers, the capsule filling machine is an important pharmaceutical equipment that helps fill up hard or soft shell capsules with medicinal substances, such as powder, granules, liquids, pellets, micro-tablets, and other medicinal ingredients.

Capsule filling machines can be industrial or for personal use. An industrial/professional capsule filling machine produces large quantities of capsulated medications, and these machines are usually fully automated.

Personal-designed capsule fillers are used to manufacture small amounts of capsules. They are primarily designed for small or medium-sized pharmaceutical businesses. Personal capsule fillers can be hand-operated or semi-automatic.

What Are Different Types of Capsule Filling Machines?

There are three most common types of capsule filling machines on the market, namely automatic, semi-automatic and manual. We will examine each capsule filling machine's composition, types, features, and operational capability as produced in HAUDA Pharma.

Automatic Capsule Filling Machine

An automatic capsule filling machine does not require a lot of manual intervention as compared to a manual capsule filler. It can produce large quantities of capsules with minimal supervision or operator assistance. In addition, an automatic capsule filling machine can efficiently fill any liquid, powder, tiny particles or fine substances into the capsule body.

If you are a pharmaceutical firm engaged in producing large quantities of capsulated medication, then an automatic capsule filling machine is your best bet. These machines can efficiently and seamlessly produce higher-grade contamination-free capsules. Also, automatic capsule filling machine machines operate with minor interference from humans and can operate to the required standard for purity in the pharmaceutical industry.

At HAUDA Pharma, we have a variety of automatic capsule filling machines that can help you effectively fill large capsules to meet the prevailing demand for your capsules. A few of our automatic capsule fillers include:

SFK-3000 Capsule Filling Machine

The SFK-3000 is a full-automatic hard shell capsule filler designed to meet the international advanced design concept, indicating that it can be used worldwide. The SFK-3000 main driver is configured using the original German-imported Novexx Solutions motor, ensuring stable production and longer machine life.

Its monolithic platen design ensures that each moving part of the machine is thoroughly sealed to prevent substances from entering or leaving the room. This helps you have a clean workstation and an energy-saving consumption. Our SFK-3000 also adopts the German SIEMENS system PLC program control for stable, safe, and reliable operation.

Features:

- Double-sealing rings ensure that the shafts are protected and prevent dust.

- State-of-the-art powder dosing system with accurate dispensing of ingredients.

- Hard-anodized aluminum surface.

- Flexible and unique modular design to serve a variety of purposes.

- Protective sleep to ensure the longer service life of critical moving parts.

SFK-700 Capsule Filling Machine

The SFK-700 is another full-automatic hard shell capsule filling machine with a distinct pressurized high-precision metering disc filling rod. It is also designed according to the international advanced design concept.

The SFK-700 is designed with an innovative tendency that combines superior craftmanship and excellent performance for a quick capsule filling process. The machine's modular construction enables it to serve various pharmaceutical capsule filling substances, such as micro-tablets, granules, powder, and pellets.

Features:

- High-quality enhanced electrical components for improved stability and durability.

- Low noise, low maintenance, easy integration, and cleanliness.

- Extended flexible modular design

- FCD700 camshaft

- SIMATIC control system, HMI touch screen, SANKYO gearbox, and NORD motor.

How Our Automatic Capsule Filling Machine Works

Automatic capsule fillers are manufactured to perform the following activities without the aid or supervision of an operator: locking, filling, and separating capsules. As a result, these devices can extensively reduce the cost of remunerating labor while increasing the manufacturing unit's production efficiency.

There are two types of automatic capsule filling machines: those that operate continuously and those that operate intermittently. Since most of the pharmaceutical sector uses intermittent motion automatic capsule fillers, we shall talk about their operation here. The working process of an intermittent automatic capsule filler includes:

- Capsule Rectification

- Separation of Capsule Cap

- Capsule Filling

- Removal or Rejection of Damaged Capsule

- Capsule Locking

- Ejection of filled capsules

- Cleaning

Semi-Automatic Capsule Filling Machine

Semi-automatic capsule filling machines are a good combination of manual and automatic capsule fillers. HAUDA's semi-automatic caspule filling machine can fill and rearrange capsules independently, thus reducing reliance on an operator. In addition, you can adjust it to manual mode if required.

The main components of our semi-automatic capsule filler are made of non-corrosive parts and stainless steel. This improves the hygiene of the production process. In addition, our semi-automatic capsule filling machines have a stable and reliable drive system that eliminates noise during operation. Its robust design also makes it highly durable and requires low maintenance.

Depending on your need or industrial capacity, we have a variety of semi-automatic capsule filling machines you can leverage to optimize your capsule production: below is an example of our semi-automatic capsule filler:

JTJ-V Vertical Type

The JTJ-V vertical semi-automatic capsule filling machine is designed to produce more accurate fillings, enable safer operation, and require simple maintenance. It results in faster production while providing a noiseless operation during use.

The JTJ-V has a dual loading system, which gives it similar capacity and efficiency to a fully automated capsule filler. This machine also boasts superior craftsmanship in its design, coupled with an independent motor and GMP design.

Features:

- Hard anodized filling rings for extended machine life.

- Organized electrical enclosures

- 10,000-hour operational capacity

- Flexible discharge chute

- Independent motor with variable speed control

- Touchscreen enabled PLC

- cGMP-compliant design

- Horizontal closing system with higher efficiency and capsule protection.

How Our Semi-Automatic Capsule Filling Machine Works

Below is the detailed workflow of semi-automatic capsule filling machine:

Step 1: First, you need to pour empty capsules into the capsule hopper. Then, pour the powder into the powder hopper.

Step 2: The capsule sowing device moves the capsules to the filling ring.

Step 3: Once the capsules are aligned, the vacuum device separates the capsule bodies from the caps. The lower ring containing the capsules is then attached to a rotary table for filling.

Step 4: By pressing the filling button, the filling nozzles are positioned above the filling ring.

Step 5: Under the control of the rotary table and the powder filling auger system, the machine fills the powder precisely into the capsules.

Step 6: Place the upper capsule tray on the lower capsule tray, then place the combination tray on the locking station and insert the ejector pins.

Step 7: The pneumatic system helps to lock the capsules and pushes the filling further into the capsules.

Step 8: At last, the ejector pins push out the finished capsules for subsequent checking and packaging steps.

Manual Capsule Filling Machine

Manual capsule fillers are hand-operated devices used to fill powders, granules or other dry ingredients into empty capsules. They are a more cost-effective option for small-scale production or personal use. This is because these capsule fillers are inexpensive, easy to use and portable.

However, for large-scale production or applications where consistency is important, investing in a semi-automatic or fully-automatic capsule filling machine is more appropriate.

This RN-100CL model below is one of the hot sellers in our cost-effective manual capsule filler series.

RN-100CL Manual Capsule Filling Machine

The RN-100CL is a state-of-the-art, improved manual capsule filling machine with a circular design. Its design combines the square and rectangular shapes of other manual capsule filling machines in the RN series. The machine is configured so it’s simple to operate and reduces the normal losses (powder waste)associated with manually filling capsules. The RN-100CL is extremely durable and doesn’t show signs of wear and tear after prolonged usage, courtesy of the transparent and glossy capsule plates embedded in its design. The capsule plates can precisely and easily align capsule caps and bodies for x2 or x3 production of capsules. Thus increasing production to about 4 or 10 times higher than a traditional capsule filler.

- Designed using PMMA material and alloy steel for extended machine life.

- Improved filling accuracy, consistency, and efficiency.

- Handles capsules of varying sizes from 000 to 5.

- Possesses a unique tamper with SUS304 cylindrical pins.

- 99.9% success rate regarding capsule closing.

Manual capsule filling machines are best used for:

- Small pharmaceutical capsule manufacturing units

- Hospitals and pharmacies

- Herbal medical providers

- Filling of formulations in Research & development laboratories

- Small volume and large encapsulation operations of various types

- Schools conducting pharmacy training

How A Manual Capsule Filling Machine Works

First, you will need to pour the capsule cap into the capsule sheet and then gently shake it into the holes of the encapsulated sheet. Once all the holes have capsule caps in them, pour the rest of the capsules into the container. You can then remove the encapsulation sheet and set the inverted capsule caps straight.

Next, secure the encapsulation sheet to the bottom sheet used to load the capsule body. Pour the capsule bodies into the bottom sheet and shake to fill each hole. Similar to the previous steps, observe if there are any inverted capsule bodies. If there is, flip it over.

It's time to start filling the capsules. First, pour the prepared powders on the bottom sheet. Then use the scraper to fill them evenly into the capsule bodies. Once all capsule bodies are completely filled with powders, remove the powder guard and scrape off the excess powder.

Place the middle sheet over the cover sheet so that the two sheets fit snugly. The two sheets are then secured to the bottom sheet. Then swing the cover and center sheet back and forth in order to gently load the capsule.

After you feel that the capsules are correctly positioned, press down with overlapping hands. Then flip the entire machine over and press down again and those capsules will lock into place correctly. Finally, you can check the finished products.

Reasons Why Your Pharmaceutical Business Should Get A Capsule Filling Machine

The ultimate aim of any manufacturing business is to increase profit while minimizing the total cost of production. For pharmaceutical companies, a capsule filling machine is a necessary device to reduce costs and increase productivity.

Here are some of the benefits that capsule filling machines bring to your business:

- The user-friendly design of capsule filling machines makes them easy to operate

- Capsule fillers are designed to meet GMP standards

- Capsule fillers can be seamlessly integrated into existing production lines

- The capsule filler helps to minimize powder loss during the production process

Get A Reliable Capsule Filler from HAUDA Pharma

HAUDA Pharma is a global leader in the manufacture of capsule filling machines. Our products are designed and manufactured using high quality materials and the best technicians in the field. If you're not sure which capsule filling machine to choose for your pharmaceutical business, contact us and let us help you professionally.