Powder Mixer Ribbon Mixer

.jpg)

Powder Mixer Ribbon Mixer WLDH1000-4000

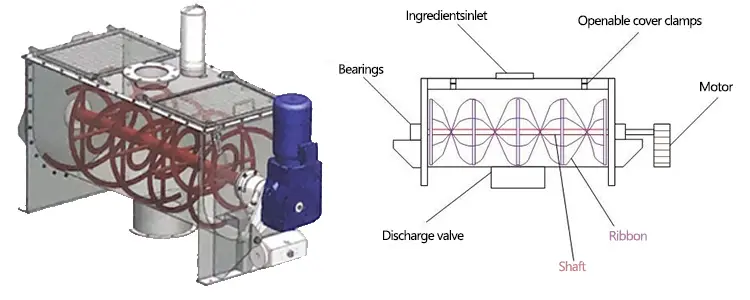

Ribbon Blenders consist of a U-shaped horizontal trough, transmission parts and ribbon agitating blades which usually have double or triple layers with outside screw gathering the material from sides to center and inside screw transmitting the material from center to sides to form convection mix and a specially fabricated ribbon agitator.

The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate at approx. 300 fpm moves materials both radially and laterally to insure thorough blends in short cycle times.

Ribbon blenders are commonly used in nutraceutical, chemical, food and related industries. It is excellent for mixing both wet and dry products.

Used in pesticides, veterinary drugs, food, chemical, biological, breeding industry, ceramics, refractory material, plastic, compound ferilizer, such as solid – solid (powder and powder) solid – plasma (i.e., powder and rubber slurry) mix,specifically adapted to viscous material mix.

We have various types of mixers, please tell us your needs, and we will recommend a suitable machine for you!

WLDH- Horizontal Spiral Ribbon Mixer Structure And Features :

Discharging mode:

Details Images

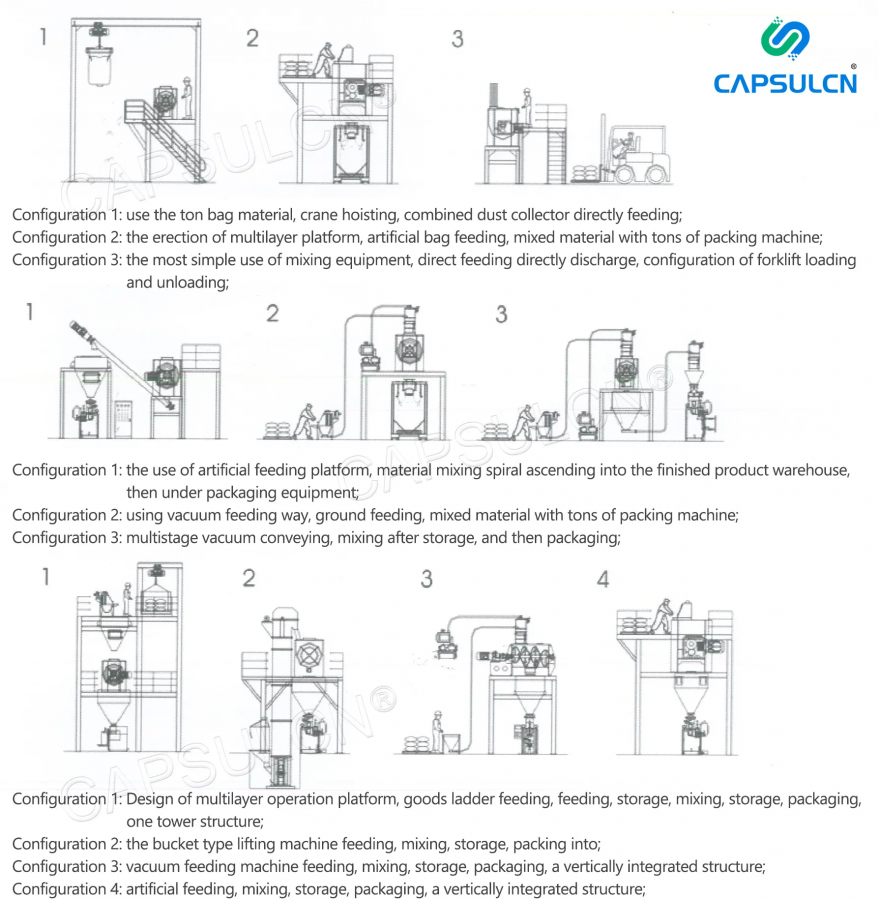

FIOW CHART :

Remarks

- The machine is fully integrated and flexible.

- The stainless steel vessel is non- corrosive and allows dense liquids to turn freely and mix thoroughly without fading.

- Materials are poured manually.

- Operator- friendly.

| Model | Total Volume(L) | Load Coefficient | Power(KW) | Dimensions(mm) | Weight (kg) |

| WLDH-100 | 100 | 0.4-0.8 | 3 | 1190x740x770 | 330 |

| WLDH-300 | 300 | 0.4-0.8 | 4 | 2030x630x980 | 720 |

| WLDH-500 | 500 | 0.4-0.8 | 7.5 | 2320x730x1130 | 980 |

| WLDH-1000 | 1000 | 0.4-0.8 | 11 | 2800x920x1320 | 1700 |

| WLDH-1500 | 1500 | 0.4-0.8 | 11 | 3180x1020x1550 | 1800 |

| WLDH-2000 | 2000 | 0.4-0.8 | 15 | 3310x1120x1640 | 2100 |

| WLDH-3000 | 3000 | 0.4-0.8 | 18.5 | 3750x12290x1820 | 3000 |

| WLDH-4000 | 4000 | 0.4-0.8 | 22 | 4220x1400x1990 | 3980 |

| WLDH-5000 | 5000 | 0.4-0.8 | 22 | 4220x1500x2100 | 4620 |

| WLDH-6000 | 6000 | 0.4-0.8 | 30 | 4700x1610x2260 | 6180 |

| WLDH-8000 | 8000 | 0.4-0.8 | 37 | 4420x2150x2470 | 8200 |

| WLDH-10000 | 10000 | 0.4-0.8 | 45 | 5520x2960x2720 | 8920 |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China