TabCN-9 pro Tablet Press

Tablet Press TabCN-9 pro

This machine is kind of automatic rotary machine for continuous tablet pressing. It is mainly used for the production of tablet in pharmaceutical industry. It is also suitable for other industries such as chemical, foodstuff and electronics to press the granular material into tablets.

Feature

-

This machine is a small tablet pressing machine for small batch production. It is the first choice to judge whether granular raw materials can be pressed into tablets.

-

Within the pressure range of the machine, it can press the granular raw materials with powder content less than 10% into round, special-shaped and lettering tablets of 5~20 mm.

-

It is mainly used for the manufacture of tablets in pharmaceutical, and it also can be applied in the chemical, food, electronic and other industries.

- Guarantees a higher output as high production levels can be achieved with a minimal amount of labor.

- Higher outputs save time and enable you to meet your large production demands.

- It reduces wastage of material.

- It allows independent control of both the weight and hardness of tablets.

Main application:

Electric Rotary Tablet Press TabCN-9 pro is a small tablet pressing machine with automatic rotation and continuous tablet pressing. Within the pressure range of the machine, it can press the granular raw materials with powder content less than 10% into round, special-shaped and lettering tablets of 5~20 mm. It is mainly used in pharmaceutical, chemical, food, electronic and other industries.

Detail images

|

|

|

|

| Peripheral Cover The peripheral cover is fully-sealed and made of Auce stainless.easy to clean without dirty corner. |

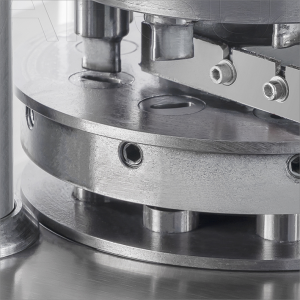

Structure Of Rotary Table The rotary table is a main component which consists of upper/lower bearings and main shaft. |

Structure Of Rail The rail is cylinder cam and plane concaved wheel consisting of upper/lower rail,as well as The track of movement of upper/lower impact lever. |

Filling-Adjustment Unit The filling adjustment unit is designed for adjusting the weight of tablets. |

|

|

|

|

| Tablet-Thickness Adjustment Unit This unit is designed for adjusting the thickness of tablet. |

Feed Unit Feed unit consists of feeder,bucket rack,column,adjustable screw and bucket. |

Outlet | Drive Components |

| Model | TabCN-9 pro |

| Punch quantity (set) | 9 |

| Max. tablet pressure (kN) | 60 |

| Max. tablet diameter (mm) | 20 |

| Max. tablet thickness (mm) | 6 |

| Max. filling depth (mm) | 15 |

| Max. production capacity (pc/h) | 14,000 |

| Turntable working diameter (mm) | 200 |

| Turntable speed (r/min) | 0~30 |

| Diameter of middle punch (mm) | 26 |

| Height of middle punch (mm) | 22 |

| Diameter of upper and lower punch (mm) | 22 |

| Length of upper and lower punch (mm) | 115 |

| Overall dimension (mm) | 480*635*1100 |

| Machine weight (kg) | 330 |

| Motor power (kW) | 2.2 |

| Voltage (V) | 220 |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw Material Processing Equipment is used for the initial processing of powders and granules, including Powder Mixing Machine, Powder Grinder Machine, Oscillating Granulator Machine, Powder Sifter Machine etc.

Tablet Press Machine

Tablet Presses from HUADA Pharma are based upon a proven design . This is due to its robust construction and durability, having a maximum compression force of 100kN and fitted with pre-compression and a rotary force feeder.

Capsule Filling Machine

capsule filling machines are ergonomically designed and of quality construction built to cGMP standards. And combine modern capsule filling technology with mechanical simplicity and robustness giving a durable and reliable machine.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Multi-channel Pill Counting Line

The HUADA Pharma bottle filling machines are multi-channel automatic counter designed to automatically count and fill tablets/capsules in to plastic as well as glass bottles/containers/jars.

Blister Machine

The HUADA Pharma Automatic Blister Packing Machines Built from top quality stainless steel to full GMP standards.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+1 (657) 670-7684

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China