Did you know? Research says the packaging machinery market will keep growing steadily—about 6.3% annually from 2025 to 2030! More and more businesses are jumping into the industry. Buying a rotary packing machine is a big step toward leveling up their packaging operations.

You might hear it called a rotary packaging machine, a rotary pouch packing machine, or a rotary premade pouch packing machine. Either way, the idea is the same—a fast-moving carousel that fills and seals ready-made pouches with your product.

If you're thinking about investing in a rotary packing machine, this guide is meant for you. It covers everything you need to know and what to watch for when buying your first one.

What Is a Rotary Packing Machine?

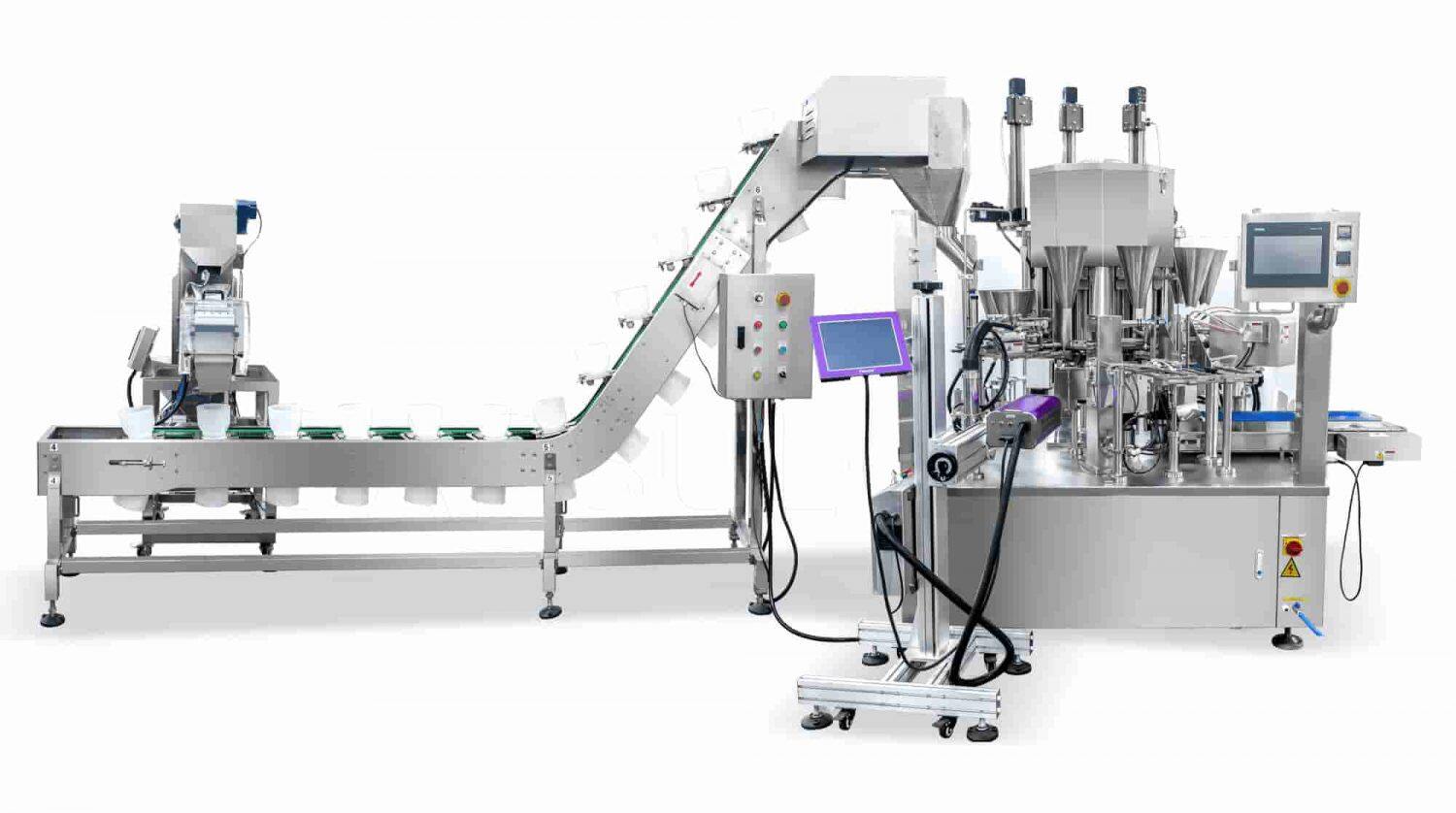

Simply put, a rotary packing machine is a system that takes care of packaging automatically. It fills and seals pre-formed pouches in a circular, rotating process.

Instead of moving packages in a straight line like some machines, it uses a rotating platform (carousel) to transfer pouches through various stations for picking up, opening, filling, sealing, and discharging. This design allows continuous operation at high speeds while taking up relatively little floor space.

Rotary premade pouch packing machines can handle various pouch styles and sizes as well as different products. Plus, they are fast, reliable, and consistent. All these make them a big hit in the food, pharmaceutical, and cosmetics industries.

How Does a Rotary Packing Machine Work?

Rotary premade pouch packing machines follow a cycle of actions at different stations around the carousel. A simplified process looks like this:

1. Bag Loading

- Premade pouches are loaded into the magazine—either by hand or automatically, depending on your setup.

- A convey system feeds the pouches into the machine.

2. Bag Gripping

- Vacuum suction pads pick up each pouch and transfer it to grippers.

- These grippers hold the pouch securely as it moves through the machine.

3. Pouch Opening & Detection

- Suction cups and opening jaws gently pull the pouch open.

- Sensors check if the pouch is present and properly opened before proceeding.

4. Filling

- The product is dispensed into the open pouch.

- Different fillers are used depending on the product type:

- Auger fillers for powders.

- Liquid fillers with nozzles for liquids.

- Multi-head scales for granules or solids.

- Counters for individual items.

5. Sealing

- The pair of heat-sealing jaws or bars is used to close the pouch.

- This step uses heat to create an airtight seal on the pouch or presses zippered pouches to close.

6. Cooling & Discharge

- The sealed pouch may pass through a cooling station to set the seal.

- Finished pouches are then released onto a conveyor or directed into a collection bin.

Main Components of a Rotary Pouch Packing Machine

A rotary premade pouch packing machine is a complicated system. In case you're new to this kind of machine, let's take a closer look at its main components.

1. Turret/Carousel: This central rotating platform moves pouches smoothly from station to station, keeping everything perfectly timed.

2. Bag Magazine & Feeder: Stores and feeds premade pouches into the machine. It typically incorporates a conveyor system to transfer the pouches.

3. Gripper Arms: Securely hold pouches as they move through each station, accommodating various pouch sizes.

4. Bag Opening System: Includes suction cups and grippers to wide open the premade bags for filling.

5. Filling System: Dispenses the product into the open pouch. It can be an auger filler, a liquid filler, a multi-head weigher, or a counter, depending on what you're packaging.

6. Sealing Mechanism: Closes the filled pouch using heat-sealing jaws or bars. For press-to-close zipper bags, it also uses pressure to shut them.

7. Cooling Device: Cools the sealed area to set the seal and prevent deformation. It's especially important for heat-sensitive products.

8. Discharge Conveyor: Carries the filled and sealed pouches away from the machine, ready for the following packaging step.

9. Control Panel (HMI): A user-friendly interface that allows operators to set parameters, monitor operations, and troubleshoot issues.

10. Safety Enclosures and Sensors: Include machine guards, emergency stop buttons, and safety interlocks. Ensure safe operation and prevent accidents. Features like "no bag, no fill" sensors help in reducing waste.

Applications of Rotary Packing Machines Across Industries

Rotary packing machines are super versatile. You'll find them working hard in all kinds of industries.

- Food & Beverage – This is where rotary packing machines really shine. They pack snacks, coffee, frozen foods, spices, sauces, candies, pet treats, and more. The airtight sealing keeps food fresh and safe from contamination, and the attractive premade pouches look great on store shelves.

- Medications & Supplements – They fill powders, pills, and medical device components in sterile pouches. The precise filling and secure sealing meet strict quality and safety standards (e.g., single-dose medicine packets).

- Cosmetics & Personal Care – They work with products like creams, shampoo sachets, face mask packets, etc. The machines can handle different pouch styles (including those with spouts or zippers) and ensure leak-proof seals for liquids.

- Chemicals & Household Products – Items like lawn fertilizers, laundry pods, and detergents are often packed using rotary packaging systems too. The machines provide a clean, leak-proof package that protects the product and handlers.

Advantages and Limitations of Rotary Premade Pouch Packing Machines

| Pros | Cons |

| Super fast, filling and sealing hundreds of pouches per minute, boosting productivity. | Significant upfront investment, especially for small businesses. |

| User-friendly touchscreen controls, easy even for beginners. | Requires regular upkeep and skilled maintenance staff. |

| Handles various pouch styles, sizes, and materials, ideal for multiple products. | Not good at dealing with sticky, oddly shaped, or very fragile products. |

| Provides uniform fills and seals consistently, reducing waste and improving quality. | Downtime occurs when changing pouch sizes or products. |

| Designed for cleanliness, excellent for food, pharmaceutical, and personal care products. | Requires considerable factory floor space, potentially challenging for smaller operations. |

| Automates packaging, saving labor costs over time. | |

| Can include gas flushing to remove oxygen, extending product freshness and shelf life. |

Key Features to Look for When Buying Your First Rotary Packing Machine

If you're buying for the first time, it's totally normal to feel a little unsure about what to look for. No worries! Check out these key features:

Speed & Pouch Size Range

Make sure the machine's throughput (bags per minute) meets your current and near-future needs, and that it can handle the pouch dimensions you use (both small and large). Also, check if it supports any special pouch types you need (e.g., zippered pouches or spouted pouches) and can seal the material your pouches are made of (including newer recyclable films).

Filling System Compatibility

The machine should come equipped with the right filler for your product. If you pack powders, you'll need an auger filler; for liquids, a liquid pump system; for pieces or granules, a multi-head weigher or volumetric filler; for capsules or tablets, a pill counting system. Ensure the filler integration is seamless. And check the spec for filling accuracy.

Build Quality & Controls

Look for a well-built machine. If you're handling food or pharmaceuticals, stainless steel construction is a must. A good machine will have a user-friendly touchscreen interface and programmable settings for different products. Features like sensors to detect missing bags, automatic error stop, and recipe memory for quick changeovers are very helpful. Modern models may even offer remote monitoring and diagnostics via IoT connectivity—a plus for maintenance.

Support & Maintenance

Consider the support offered by the manufacturer. Is training provided? What about warranty and spare parts availability? A first-time buyer should prioritize suppliers known for responsive after-sales service. Also, check how easy it is to clean and maintain the machine. Features like tool-less removal of contact parts or clear maintenance schedules can save you headaches later.

Rotary Packing Machine Price Ranges in 2025

| Machine Level | Price Range (USD) | Typical Features | Best For |

| Entry-Level | $10,000–$20,000 | Basic speed, fewer stations, straightforward filling & sealing functions. | Small startups, pilot production runs, or businesses on a tight budget. |

| Mid-Range | $30,000–$60,000 | Moderate speed, standard automation, multiple pouch sizes and materials, better control systems. | Growing businesses needing consistent production volumes and flexibility. |

| High-Performance | $80,000 and above (often nearing six figures) | High speed, advanced automation, vacuum/gas flush sealing, multi-lane processing, specialized product handling, superior build quality. | Large-scale producers or those requiring specialized packaging and high throughput. |

Additional Costs to Consider:

- Installation: Set aside funds for setup and integration with your existing systems.

- Training: Budget for training your team to operate and maintain the machine safely and efficiently.

- Shipping & Logistics: Don't overlook delivery charges, import fees, and related logistics expenses.

Always request a customized quote reflecting your specific requirements to avoid unexpected surprises.

Tips for First-Time Rotary Packing Machine Buyers

Do Your Homework

Outline your needs (product, pouch size, speed) clearly and research multiple suppliers. Compare models, ask for quotes, and check out real user feedback. Never hesitate to reach out to the supplier if something isn't clear. If possible, see a demo. Send your product for a test run or watch videos of the machine in action. The more you know, the more confident you'll be in your choice.

Plan for Training & Maintenance

Ensure you get proper training from the manufacturer during installation. Designate someone on your team to become the in-house expert on operating and maintaining the machine. Set up a routine maintenance schedule right away (daily cleaning, periodic checks of parts, etc.). Keeping up with maintenance will prevent costly downtime.

Choose the Right Machine Size

Match the machine's capacity to your business needs. Don't overspend on a super high-speed model if you're a small operation, but also try not to outgrow your machine immediately. Estimate your production needs for the next couple of years. It's wise to buy a machine that can handle a bit more than your current volume, but avoid paying for features you don't actually need.

FAQs about Rotary Packing Machines

Q: What is the difference between a rotary packing machine and other packaging machines?

A: A rotary packing machine moves premade pouches in a circle through filling and sealing stations. By contrast, other machines (like vertical form-fill-seal systems) form their own bags from film and often use a straight-line layout. The rotary system is more compact and uses premade pouches, which can mean quicker changeovers and a smaller footprint.

Q: Is it possible to run different products and bag sizes on the same rotary pouch packing machine?

A: Yes, within limits. A single rotary pouch packing machine can be adjusted to run various pouch sizes and can use different filling attachments for different products. You might need to swap out some parts or change settings when switching from, say, a powder to a liquid, but you generally don't need a whole new machine for each product type.

Q: How much does a rotary packaging machine cost?

A: It varies. In 2025, basic rotary packaging machines might cost around $15,000–$30,000, while larger, high-speed models with more features can be $50,000 to $100,000 (or even beyond). Always get a tailored quote for your specific requirements.

Q: What maintenance does a rotary premade pouch packing machine require?

A: Plan on regular cleaning, lubrication, and replacing of wear parts (like sealing elements) periodically. Following the manufacturer's recommended daily, weekly, and monthly maintenance schedule will keep your machine in good shape and help prevent breakdowns.

Q: Is a rotary packing machine hard to operate for a beginner?

A: No, not really. Modern rotary packing machines come with easy-to-use touchscreens and built-in safety sensors. While training is needed to learn the setup, most new users become comfortable operating the machine after some practice. Manufacturers usually provide training with the purchase, so you'll have guidance. With a bit of hands-on time, running the machine becomes routine.