CapCN-450C Capsule Filling Machine

Fully Automatic Capsule Filling Machine CapCN-450C

CapCN-450C automatic capsule filler processes the products for optimal productivity up to 7500 capsules per minutes, featuring low-maintenance operation, minimal downtime, and overall dependable production.

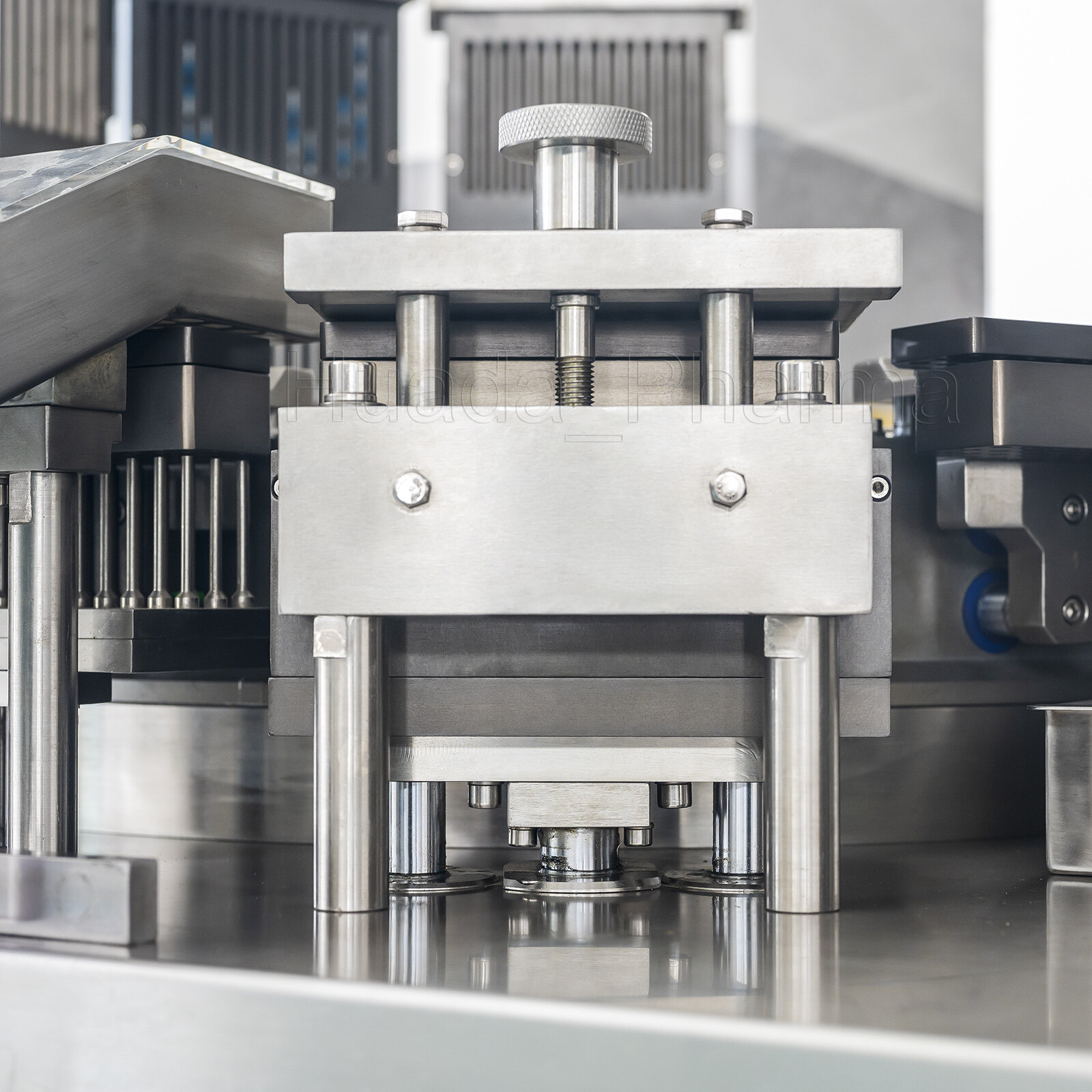

Powder dosing uses the 5 stage tamping technology for an enhanced accuracy. Filling of pellets is available.

Capsules from the bunker are fed into the orienting device along the vertical guide.

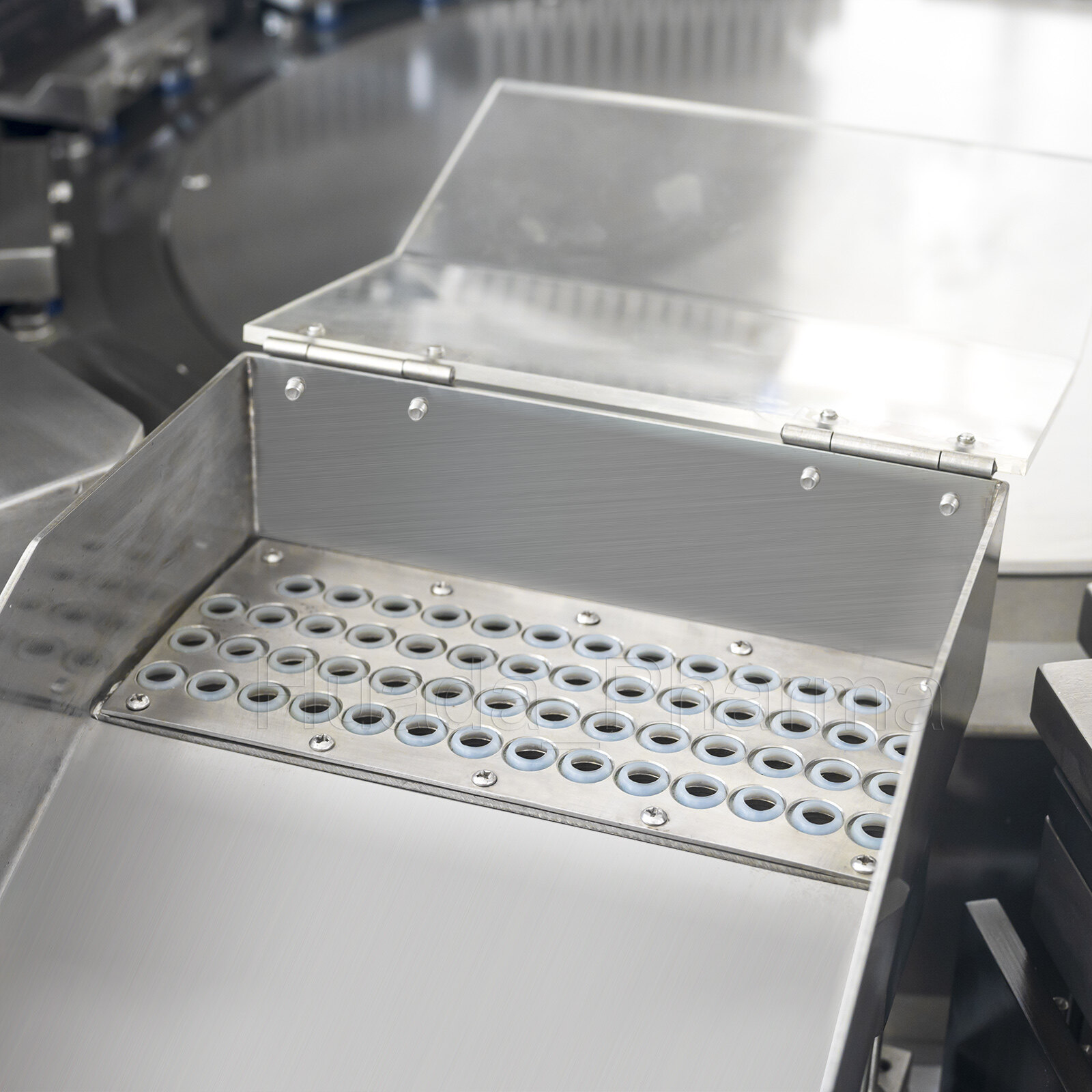

Then they are transferred into special cells on the rotor. Here the capsule is separated, after what the bottom part comes to the filling position.

After filling the bottom part with the material, on next positions the non-separated capsules are rejected, and the filled bottom parts are joined with top parts, counted and taken away into the receiving box.

Introduction

NJP-7500C automatic capsule filler processes the products for optimal productivity up to 7500 capsules per minutes, featuring low-maintenance operation, minimal downtime, and overall dependable production.

Powder dosing uses the 5 stage tamping technology for an enhanced accuracy. Filling of pellets is available.

Capsules from the bunker are fed into the orienting device along the vertical guide.

Then they are transferred into special cells on the rotor. Here the capsule is separated, after what the bottom part comes to the filling position.

After filling the bottom part with the material, on next positions the non-separated capsules are rejected, and the filled bottom parts are joined with top parts, counted and taken away into the receiving box.

The equipment design is fully in line with the requirements of CGMP and FDA specification.

Remarks

- cGMP design with emphasis in powder dust handling: Enclosed main turn table avoid dust getting into mechanical parts.

- Automatic control for capsule and powder supply.

- PLC control for reliable operation. Touch Screen HMI, featuring user friendly controls: production counter, manual / automatic / parameter setup modes, alarms.

- Precision capsule segments and dosing disk minimizes adjustments following parts changeover.

- SS 304 stainless steel frames and transparent safety interlock guards.

| Model | CapCN-450C |

| Max capacity | 450,000capsules/hour |

| Suit for capsule size | 00#~5# |

| No. of Mould Bores | 54 |

| Power | 380/220V,50/60Hz,13.5kW |

| Noise | <75dB |

| Machine dimensions | 1700x1220x2150mm |

| Net weight | 3,800kg |

| cGMP | ✔ |

| PLC control | ✔ |

| safety interlock guards | ✔ |

✔: Yes 🔘: Optional

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China