Turntable Cartoning Machine

Turntable Cartoning Machine DZH-50S

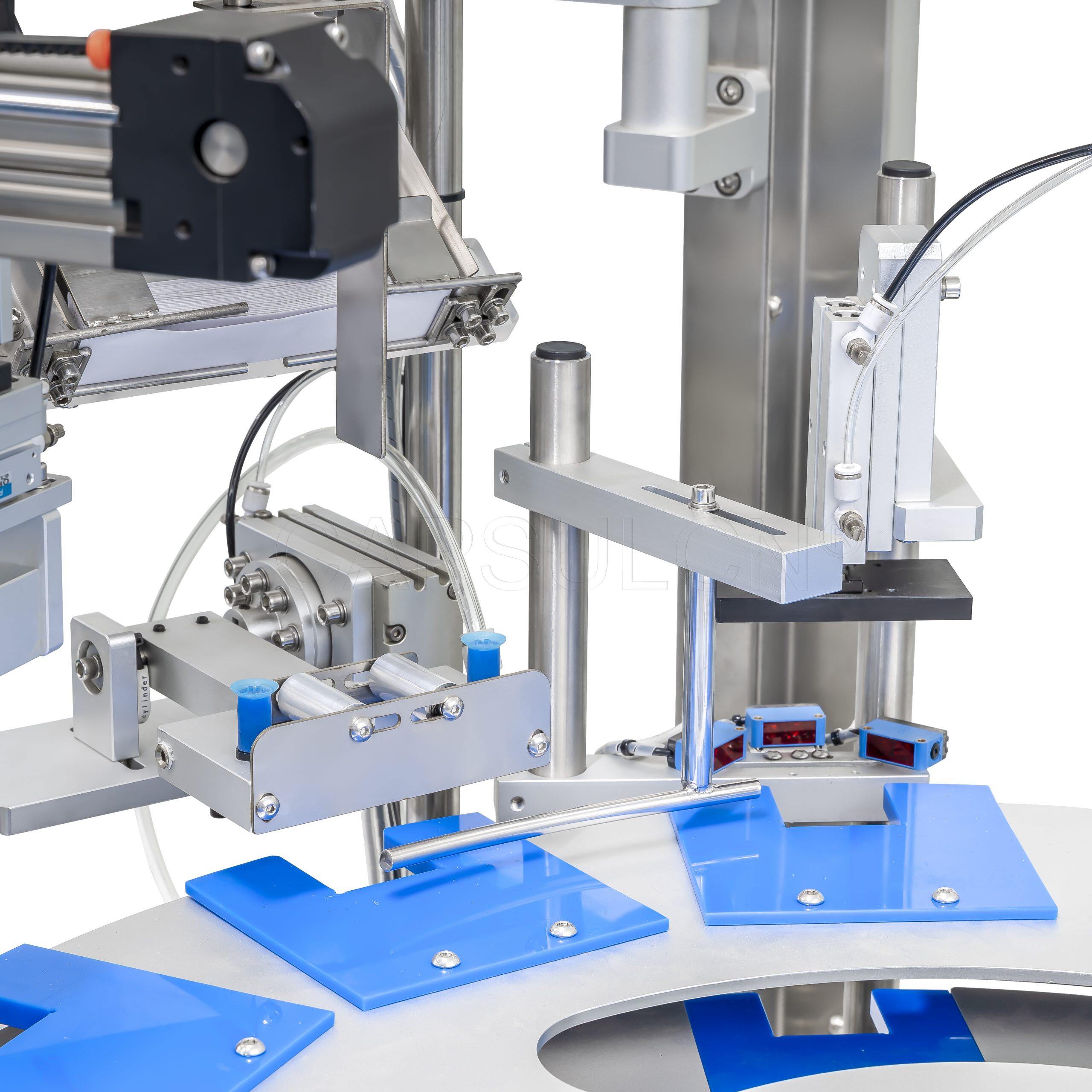

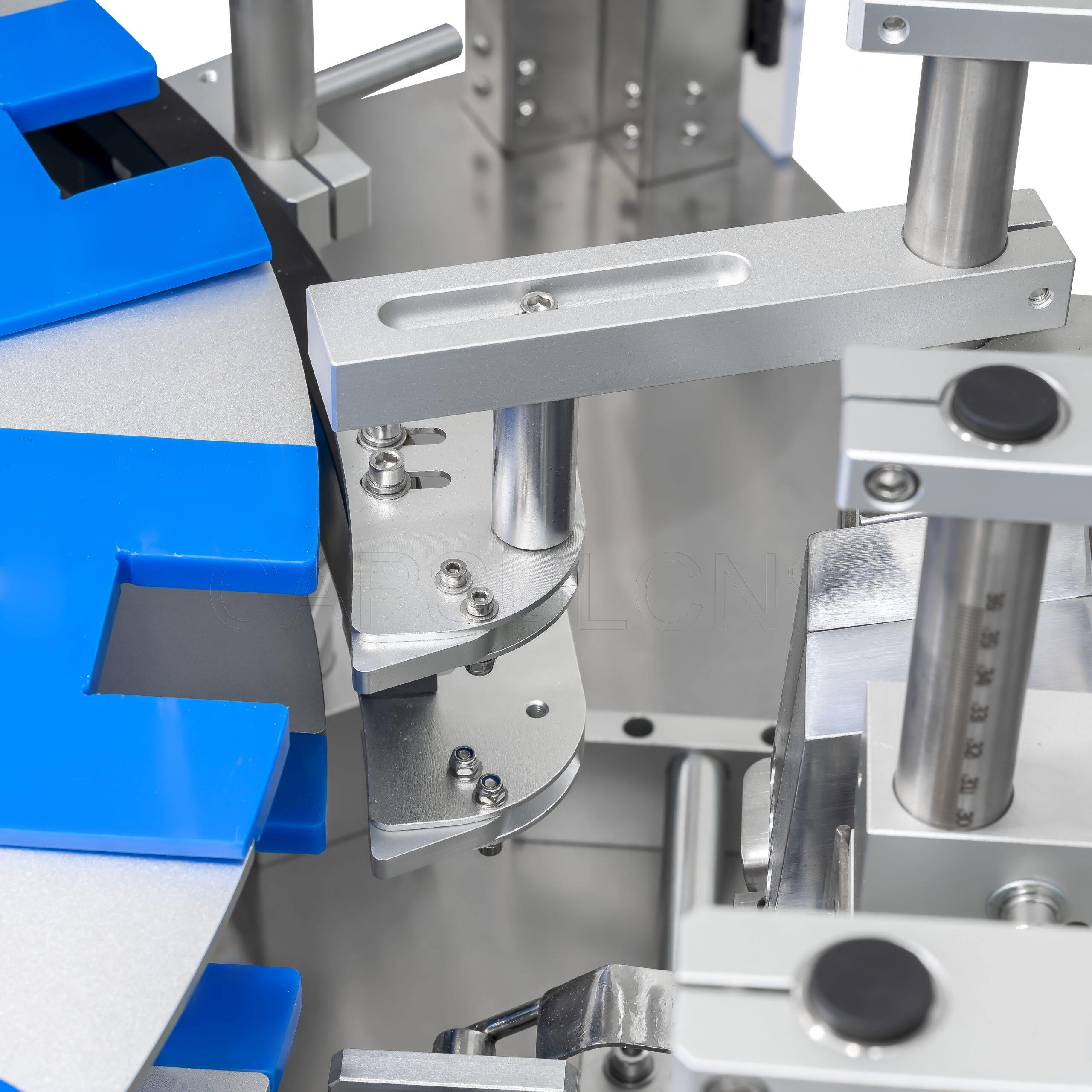

This machine uses vacuum suction cups to feed cartons into the star wheel. The empty cartons are rotated by the star wheel to the folding mechanism 1 to seal the bottom of the carton. After the finished product to be packed is manually placed into the carton, the star wheel rotates the carton to the folding mechanism 2 to seal the top of the carton. Finally, the completed product is transferred by the star wheel to the carton pushing-out mechanism for delivery.

Main Application

It is applicable to the packaging of all kinds of medicine, food, cosmetics and so on.

Details Images

Main Features

- This machine has the characteristics of compact structure, advanced performance, convenient use and easy understanding.

- It is controlled by a programmable controller of world-renowned electronic components, and is equipped with a touch-type human-machine interface, which can quickly and easily set parameters.

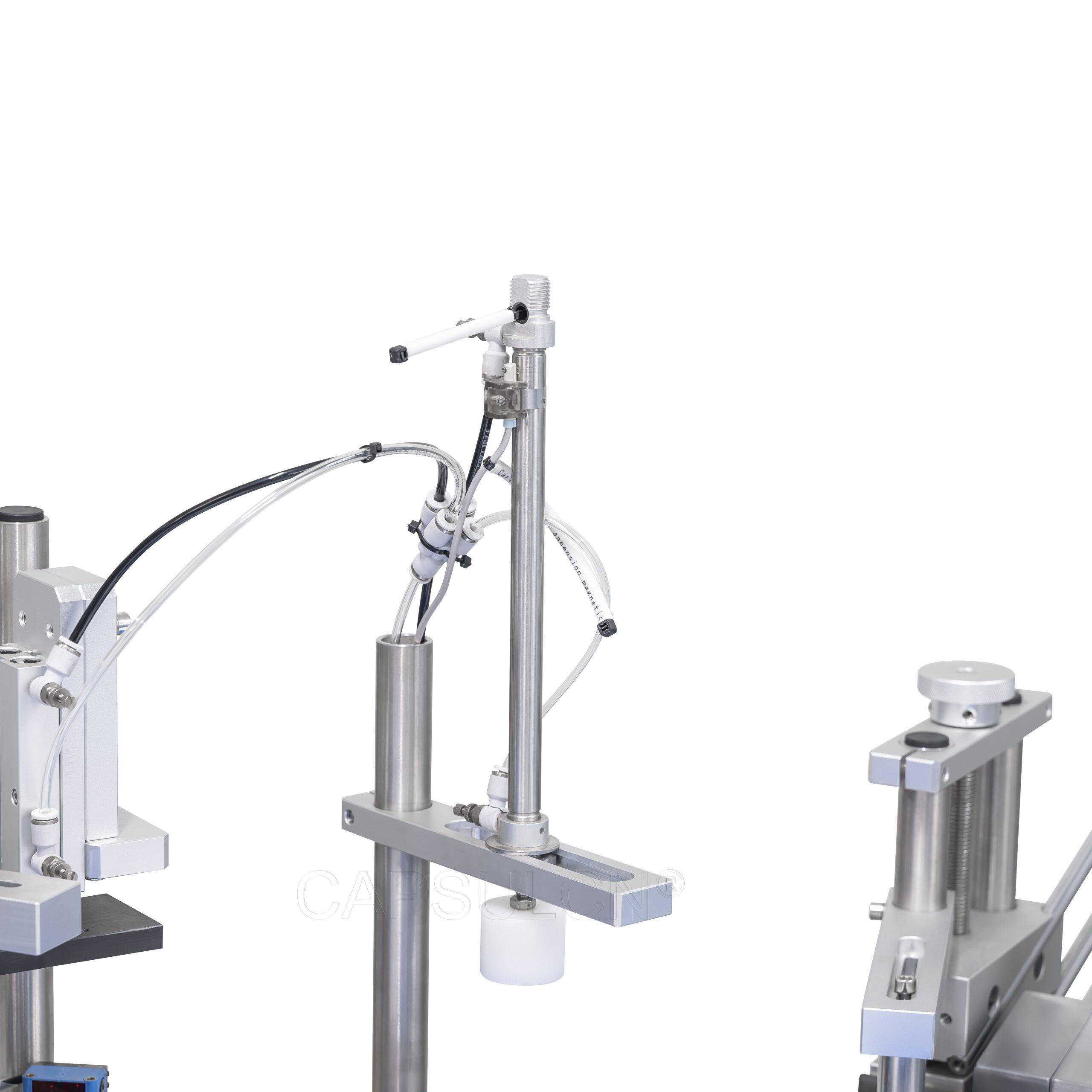

- This machine uses a vacuum generating device or a vacuum pump to pump the carton, and the positioning is accurate, and it will not be stuck on the carton.

- Each operation is completed by software, which facilitates function adjustment and technology update, and meets the production needs of different stages.

The local workflow consists of the following six parts.

- The vacuum suction cup device on the carton feeding mechanism holds the carton and feeds it into the star wheel fixture, then a set of cylinders from below fold the inner small flaps.

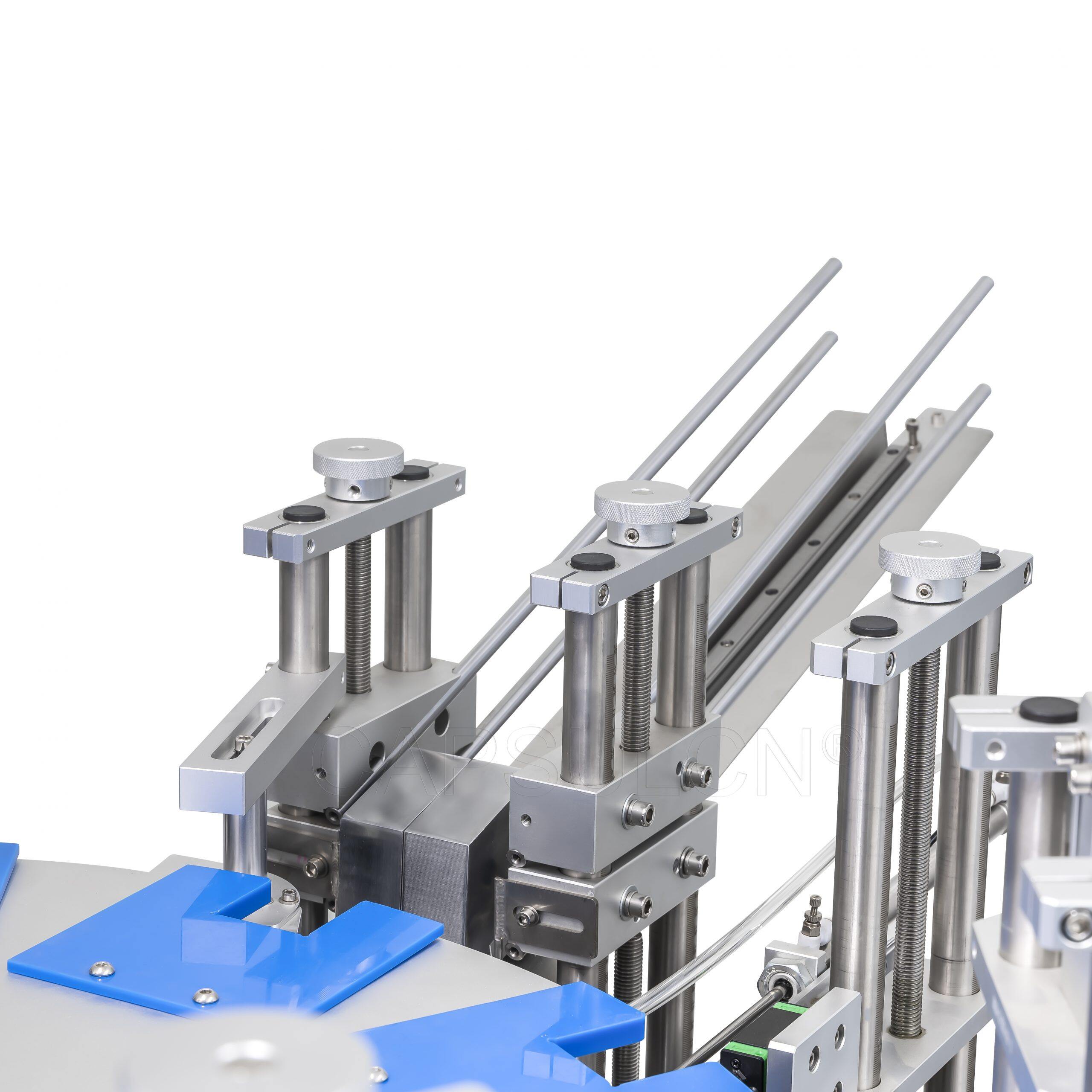

- After the carton is transferred to this station, the stopper cylinder on the ear folding mechanism 1 blocks the large ear, and the ear folding cylinder folds the large ear into the carton, followed by the flattening of the large ear by the ear pressing cylinder.

- Place the desired items into the carton.

- The rotating cylinder on the ear folding mechanism 2, together with the ear pressing rod, folds the inner small flaps on the top of the carton.

- After the carton is transferred to this station, the stopper cylinder on the ear folding mechanism 2 blocks the large ear, and the ear folding cylinder folds the large ear into the carton, followed by the flattening of the large ear by the ear pressing cylinder.

- After the finished product of carton folding is transferred to this station, a set of pushing cylinder pushes the finished product out of the star wheel.

Maintenance and Care for Machine

- Keep the machine clean by wiping it regularly and occasionally tightening screws near the cylinder to prevent loosening.

- In case of malfunction, analyze carefully and have relevant mechanics repair and troubleshoot. Do not adjust or dismantle components at will to avoid damaging the machine.

| Model | DZH-50S |

| Carton minimum dimensions | 60×20×20m/m |

| Carton Maximum dimensions | 200×80×80m/m |

| Production speed | 20-60 cartons/min |

| Power supply | 220V single phase; 50/60Hz |

| Horsepower of motor | 1/4HP 15:1 |

| Air pressure consumption | 150L/min |

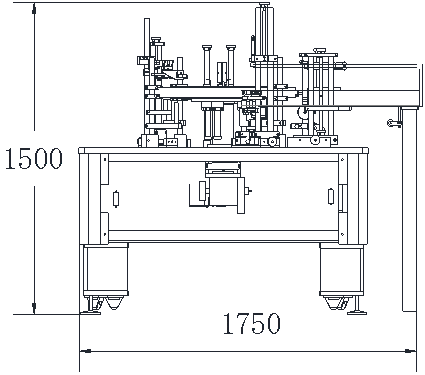

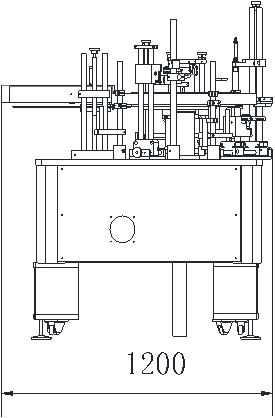

| Machine dimensions | 1750L×1200W×1500H |

| Machine weight | 950kg |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China