Integrated Automatic Bottling Line For Capsule / Tablets

Integrated Automatic Bottling Line For Capsule / Tablets

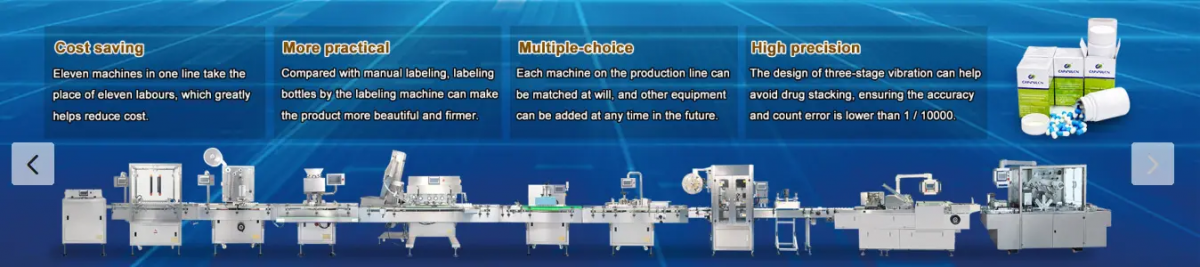

Eleven machines cooperate perfectly

* You can choose the complete line or just several machines of it, which is based on your own needs.

* As each machine cooperates perfectly in order, it greatly improves not only the efficiency but also the quality and grade of product packaging.

Bottle Unscrambler—Bottle Cleaning—Desiccant Inserter—Counter—Capper—Induction sealer—Labeler—Cartoner—Overwrapper

Designed to comply with FDA and cGMP regulations

Different capacity ranges from 30BPM to 200BPM

Customize your own counting line

- Cost saving——Eleven machines in one line take the place of eleven labours, which greatly helps reduce cost.

- More practical——Compared with manual labeling, labeling bottles by the labeling machine can make the product more beautiful and firmer.

- Multiple-choice——Each machine on the production line can be matched at will, and other equipment can be added at any time in the future.

- High precision——The design of three-stage vibration can help avoid drug stacking, ensuring the accuracy and count error is lower than 1/10000.

Detail images

|

|

| High-speed Bottle Unscrambler Used for loading and oriented supply of round/square plastic containers to the automatic line . |

Automatic Bottle Air Cleaning Machine It is an automatic cleaning device for different kind of bottles, which has increased the labor productivity greatly and avoid the cross contamination and microbiological pollution caused by manual cleaning. |

|

|

| Automatic Desiccant Sachet Filling Machine The machine can automatically cut the belted desiccant and insert the desiccant bag into the container accurately and speedily. |

Eight-channel Counting Machine It adopts the internationally advanced 8-channel vibration, computer control, dynamic scanning counting, automatic bottle conveying and photoelectric control. |

|

|

| High-speed Cap Screwing Machine PLC control and digitized system make the operation simple, effective. It can work alone, or can be connected to filling machine, labeling machine etc. |

Automatic Foil Sealing Machine Applicable to various round bottles and partial irregular-shape bottles. Adopts automatic detecting and rejection device for no alu.foil to ensures the qualified rate.The cap with no foil will be rejected automatically. |

|

|

| Self-Adhesive Labeling Machine Printing the codes by the print system and Removing the unit label from the label ribbon and labeling on the bottle smoothly and accurately by the Roller. It designed strictly according to pharmaceutical GMP standard and technological requirements. |

Bottle Tidying Rotary Table It is suitable for automatic transmission of round bottles and square bottles, such as conveyor belt connected to labeling machine, filling machine and capping machine, which can automatically convey bottles to improve efficiency. |

|

|

| Automatic Sleeve Labelling Machine With built-in blade, the shrink film is cut based on the way of planetary matching and the deflection crankshaft steel structure. The whole machine is made of aluminum alloy together with anodization and 304 stainless steel. |

Automatic Cartoning Machine Cartoning machines are packaging systems which erect, close /or erect, fill and close carton blanks or folded and side seam sealed cartons. |

|

|

| Automatic Film Box-Type Packing Machine Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes. |

(Don’t Worry! We have several Models, We can recommend you according to your requirement.) |

Remarks

- With special patented flap partial filling system ,the discharging of medicine is homogeneous and stable without damage.

- Adopting the anti high dust photoelectric sensing technology, it also can work stably under the high dust circumstance.

- Photoelectric sensor can check automatically if there’s no bottle and stops automatically.

- Easy to operate, disassembly, clean and change the components without any tools.

- Adopting intellectualized design, all kinds of operation data can be set according to the requirement. It can store 10 groups of setting parameters for use.

| Model | PBDS-8 | PBDS-12 | PBDS-16 | PBDS-24 |

| Production capacity | 10~50 bottles per minute | 20~55 bottles per minute | 60-100 bottles per minute | 80-150 bottles per minute |

| Container size | Dia.:20~100mm Height:50-100mm |

Dia.:20~100mm Height:40~200mm |

Dia.:20~100mm Height:40~220mm |

Dia.:20~100mm Height:40~220mm |

| Size of capsule/tablet | Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

| Main Power | 0.4kw | 1.5kw | 1.5kw | 1.7kw |

| Power Supply | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz |

| Weight | 280kg | 300kg | 360kg | 580kg |

| Overall Dimensions | 1600x1500x1600mm | 1600x1500x1600mm | 2600x1600x1600mm | 4200x1800x1600mm |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China