Semi-Automatic Gummy Machine

Semi Automatic Gummy Machine

The semi-automatic gummy machine integrates key functions such as heating, mixing, and depositing. The semi-automatic gummy machine includes a syrup dissolving kettle, a gummy depositing machine, and a demoulding machine. The production line is an advanced continuous equipment. The semi-automatic gummy machine is the ideal equipment for producing high-quality gummy bears, jelly gummies and other gummies.

The semi-automatic gummy machine supports a variety of mold specifications. So the shape and size can be easily customized to meet the requirements of different markets. Our gummy making machines are made of food-grade materials and meet strict hygiene standards to ensure product quality.

The semi-automatic gummy machine is simple to operate and efficient. Whether it is a small-scale trial or a medium-scale production, the semi-automatic gummy machine can help users achieve high-quality production while saving costs.

Semi-Automatic Gummy Machine Introduction

The machines on the semi automatic gummy production line include syrup dissolving kettle, gummy depositing machine, candy/gummy demolder, and mould. We will show you the pictures and specific specifications of each semi automatic gummy machine to help you better choose the product.

CndCN-Pot S100L Tilting Syrup Dissolving Kettle

This tilting syrup dissolving kettle is used to heat and dissolve raw materials such as sugar, water, gelatin or pectin. After the required ingredients are mixed into syrup, the machine can be tilted and the syrup can flow out. Syrup dissolving kettles are usually equipped with stirring function and temperature control system.

Tilting Syrup Dissolving Kettle Specifications

| Model | CndCN-Pot S100L |

| Temperature | 0-145℃ |

| Capacity | 100L |

| Power | 13kw |

| Reducing ratio | 1:60 |

| Temperature control table | Omron |

| Motor | Siemens |

| Heating mode | Eclectic |

| Size (mm) | 1300*800*1250 |

| Peso | 200 kg |

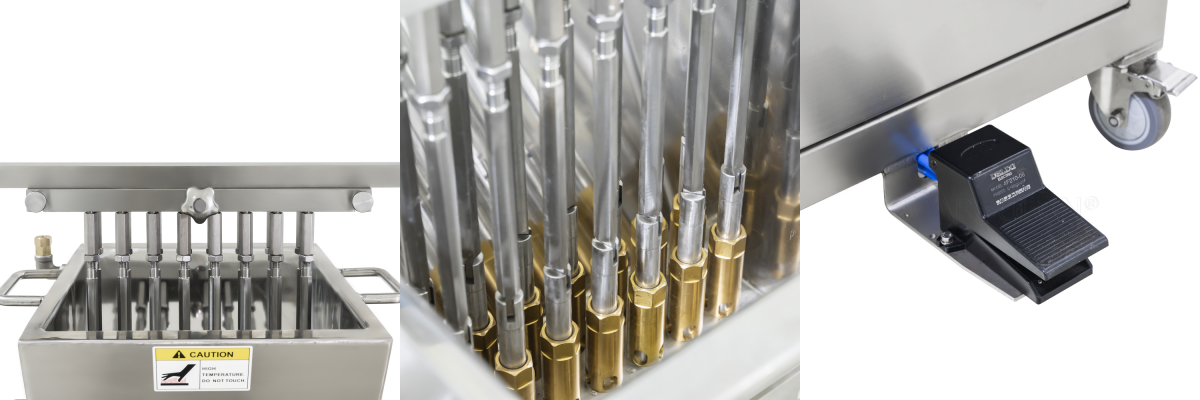

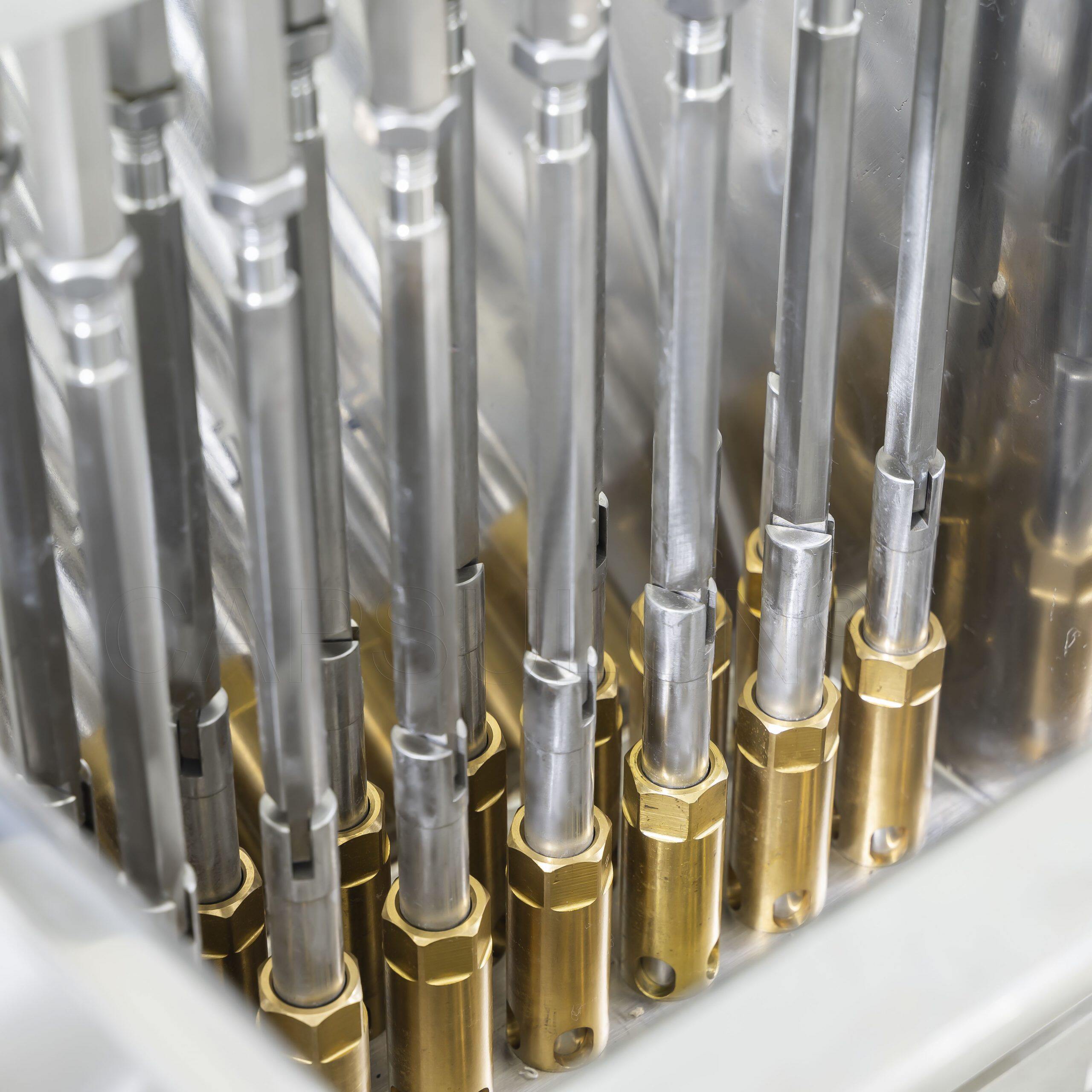

Semi-automatic Pedaled Gummy Depositing Machine CndCN-Mol S20

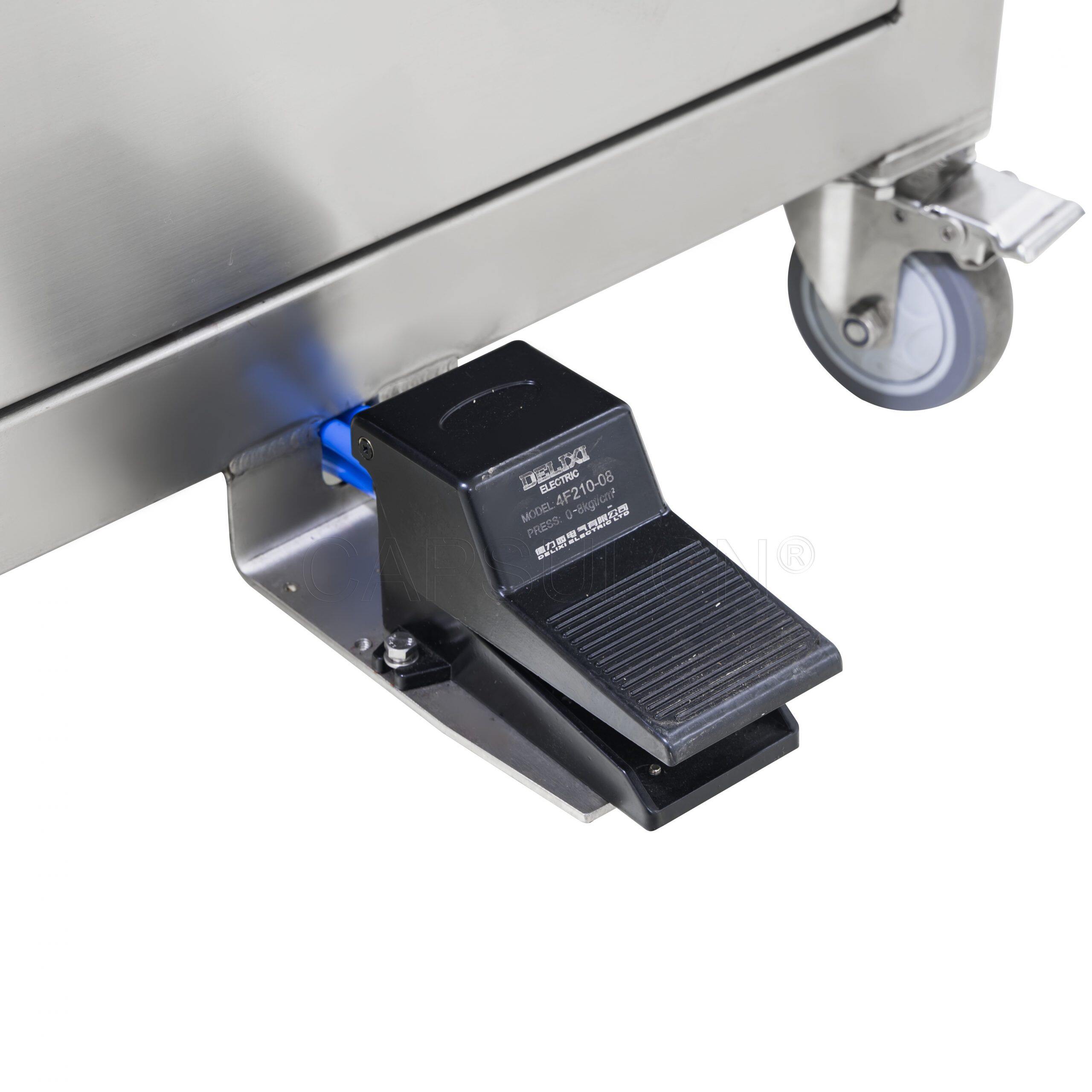

This is a semi-automatic gummy depositing machine that can deposit various shapes of candies. Put the mold under the depositing hopper by hand, then deposit it, and take out the mold after depositing.

Gummy Depositing Machine Specifications

| Model | CndCN-Mol S20 |

| Power | 4 kw |

| One-time depositing | 20 pcs (candy quantity can be customized) |

| Depositing Speed | 10-30n/min |

| Material | SUS 304 |

| Capacity | 30L |

| Production Capacity | 30 – 50 kg / h |

| Size(mm) | 800*800*1700 |

| Weight | 200 kg |

Semi-automatic Candy/Gummy Demolder CndCN-Dem S

This is an optional equipment that can remove the solidified gummy from the mold. This equipment is suitable for semi-automatic production lines and can effectively improve production efficiency.

| Model | CndCN-Dem S |

| Material | aluminum alloy |

| Production Capacity | 30 – 50 kg / h |

| Size(mm) | 420*220*500 |

| Weight | 15 kg |

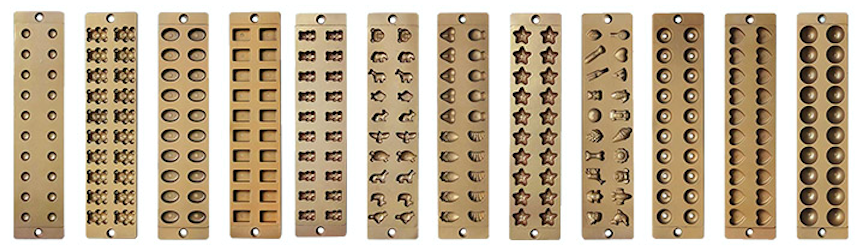

Semi-Automatic Gummy Machine Mould (shape can be customized)

Gummy Candy Samples

| Model | CndCN-Pot S100L |

| Temperature | 0-145℃ |

| Capacity | 100L |

| Power | 13kw |

| Reduction ratio | 1:60 |

| Temperature control table | Omron |

| Motor | Siemens |

| Heating style | Electic |

| Size(mm) | 1300*800*1250 |

| Weight | 200 kg |

| Model | CndCN-Mol S20 |

| Power | 4 kw |

| One-time depositing | 20 pcs (candy quantity can be customized) |

| Depositing Speed | 10-30n/min |

| Material | SUS 304 |

| Capacity | 30L |

| Production Capacity | 30 – 50 kg / h |

| Size(mm) | 800*800*1700 |

| Weight | 200 kg |

| Model | CndCN-Dem S |

| Material | aluminum alloy |

| Production Capacity | 30 – 50 kg / h |

| Size(mm) | 420*220*500 |

| Weight | 15 kg |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China