LiqCN-4V Serum Vial Filling and Closing Monoblock

LiqCN-4V Serum Vial Filling and Closing Monoblock

LiqCN-4V Vial Filling and Closing Monoblock is design to fill and close vials up to 40 cpm. With this Monoblock system, the manufacturing process is simplified by combining the bottle filler and capper into a single space-saving machine. The isolation barrier will work with laminar flow in a clean environment. This Monoblock machine is great for products in pharmaceutical and food industries. Each ACCUMOST Monoblock system is specifically constructed to the individual product specifications, space constraints, and production environment to maximize product output. It is an easy to use system with a simple and intuitive touch screen display.

Peristaltic filling configuration is used to enhance easy clean and high accuracy. Tubing will be tested by ACCUMOST validation and technical service engineers based on your application to assure compatibility.

- 304 Sanitary Stainless Steel frame configured to project specifications

- Tooling for one bottle and cap

- 316L Stainless Steel Head Filling with 4 nozzle ports

- Servo controlled stoppering head

- Straight through, side mount filling nozzle

- Vibratory sorter bowl for transition of caps and stoppers for placement on vials

- PLC Touch screen with HMI interface for easy setup and monitoring

- Motorizing system for the movements of various groups

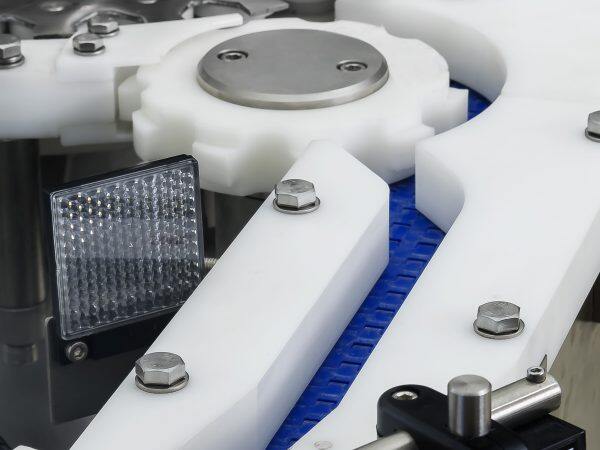

- 16 positions star-wheel with intermittent movement. The Alternative movement of the star is made by an intermittent mechanical transmission. Vial presence control in the star. If the presence of the vial is not noticed the machine stops automatically.

- Presence control of stoppers on the vial. If the control has a negative outcome, the machine stops. Alternatively the machine can reject the defective object.

- All non-metal material will be designed for compatibility with customer’s disinfectants.

- Hopper or bowl mounting with ergonomic design for single person operation

- Capable of assigning user rights to a group; user access matrix available

- HMI CFR 21, Part 11 compliant; Audit Trial is viewable/exportable

- FAT service included

- Optional pFMEA, SAT and IOQ available

| Model: | LiqCN-4V |

| Length: | 80” |

| Width: | 45” |

| Height: | 70” |

| Weight: | 1,750 lb. |

| Filling Nozzles: | 4 |

| Stopper Placer: | 1 |

| Closing Head: | 1 |

| Accuracy: | ± 1.5% |

| Reject Rate: | Less than 0.2% |

| Electrical Requirements: | 220V/50Hz (opt. 380V) |

| Air Requirements: | 85 psi. @8 cfm |

| Range: | 0-100mL |

| Output: | up to 40 CPM |

| Finish: | Stainless steel and plastics |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China