CW-Double Cone Mixer

Double Cone Mixer CW200/300/500/1000/1500/2000/5000

The CW-Double cone mixer is a kind of equipment for mixing dry powder or dry small granular materials, suitable for pharmaceutical, chemical, food, agricultural and other industries.

The double-cone mixer has a unique structural design, the mixing container rotates, and the materials in the container move in multiple directions during the rotation process, so that the materials in the container have more mixing points, the effect is good, the mixing uniformity is high, and the maximum loading coefficient is 0.7 .

When the double-cone mixer is mixing, the rotation axis deviates from the center of the mixing container at an angle. When the container rotates, the material diffuses, flows and tangentially moves, so that the mixed material is carried out between materials under the action of frequent and rapid rotation and turning. The diffusion, shrinkage, flow and tangential movement of the material make the materials mix with each other from their respective states, ensuring that the materials meet the ideal mixing requirements in a short time.

Structure:

1. Machine base: It is composed of structural parts and stainless steel panels, and is equipped with transmission system and electrical appliances.

2. Transmission system: It is composed of belt, reducer, sprocket and other transmission mechanisms.

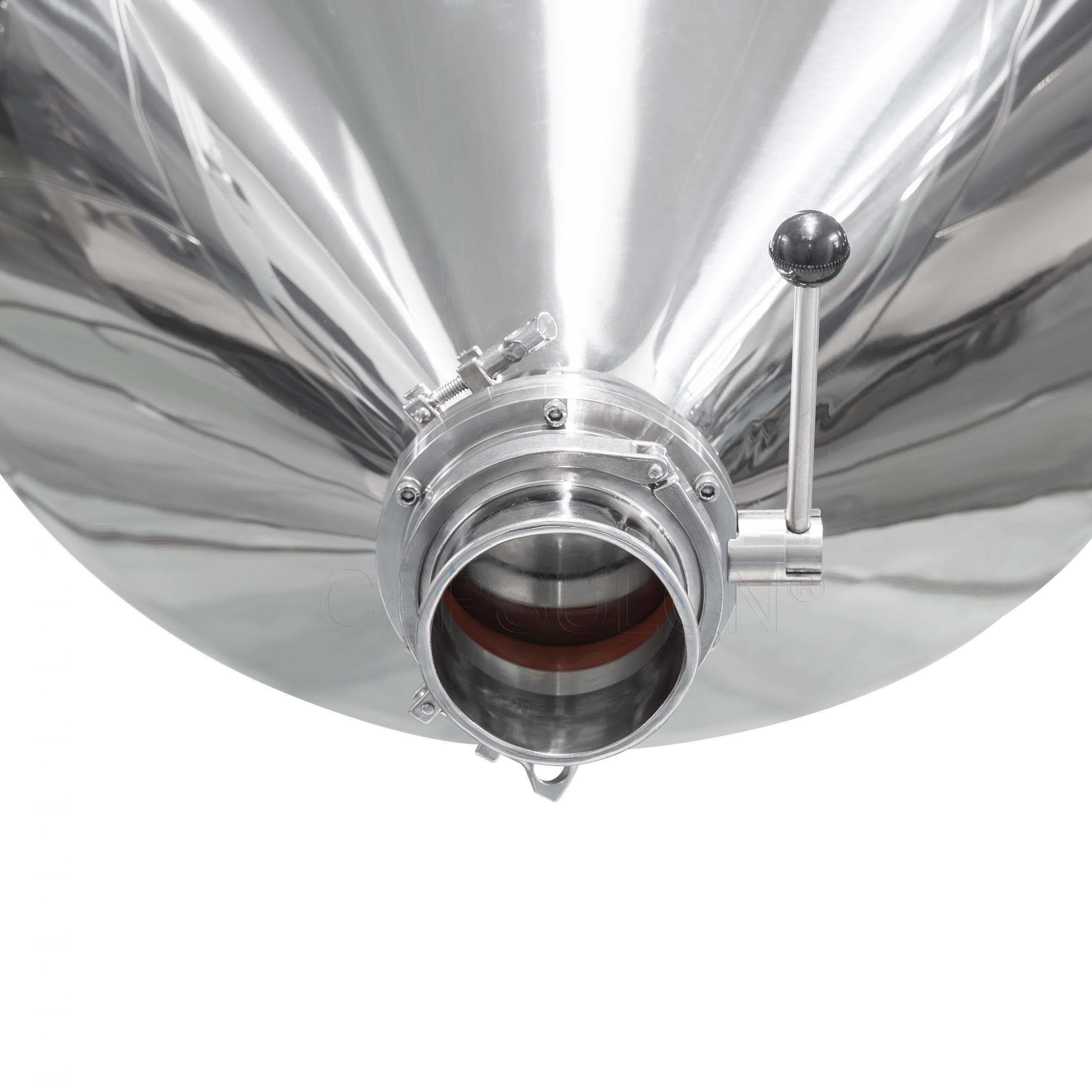

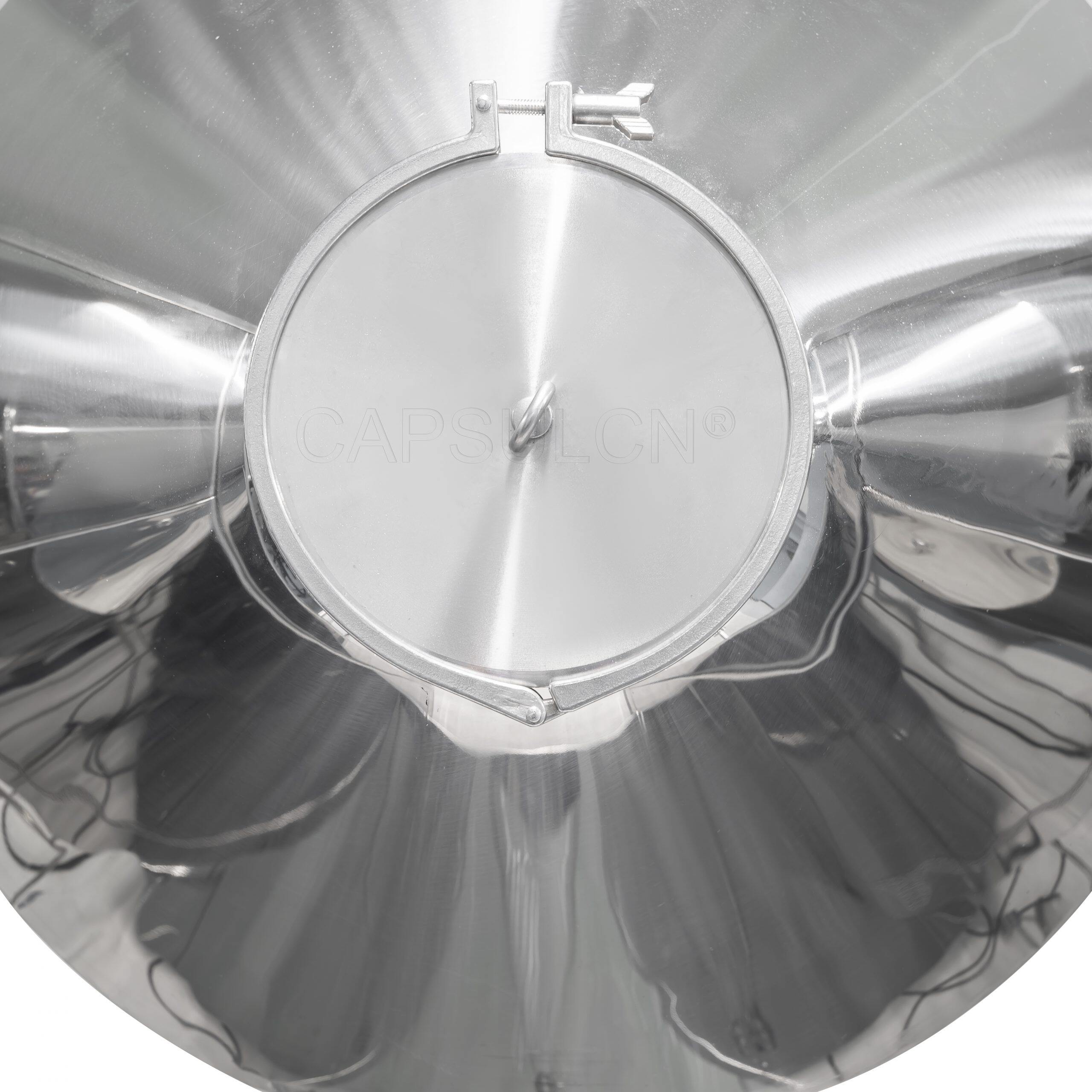

3. Mixing container: The double-cone special structure is made of high-quality stainless steel, the inner and outer surfaces are polished, no dead angle, easy to clean, in line with GMP requirements, and the discharge is controlled by a butterfly valve. The material is discharged smoothly under the action of its own weight. No accumulated material, no cross-contamination and other advantages.

Remarks

- Before the initial installation and test run, it needs to run empty for 10-30 minutes to ensure that the mixer is not damaged during the installation process and that there is no friction in the transmission parts.

- It is strictly forbidden to put long fibers or hard materials into this equipment.

- When the initial installation is completed, lubricating oil of the corresponding label must be injected into the reducer, and the lubricating oil will be replaced every 3 months thereafter.

- The wearing parts of the mixer should be replaced regularly according to the actual situation.

| model | W-200 | W-300 | W-500 | W-1000 | W-1500 | W-2000 | W-5000 |

| Full volume (L) | 200 | 300 | 500 | 1000 | 1500 | 2000 | 5000 |

| Maximum charging volume (L) |

100 |

150 |

350 |

700 |

1050 |

1000 |

2500 |

| Maximum charge weight (kg) |

100 |

150 |

210 |

420 |

630 |

1000 |

2500 |

| Motor power (KW) | 1.1 | 1.5 | 2.2 | 4 | 5.5 | 7.5 | 18.5 |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China