Dry Granulator Machine

Dry Granulator Machine RawCN-Gra D10/100

Dry granulators are used for dry granulation process. The dry granulation process is used to form granules without using a liquid solution because the product to be granulated may be sensitive to moisture and heat. Forming granules without moisture requires compacting and densifying the powders. In this process, the primary powder particles are aggregated under high pressure.

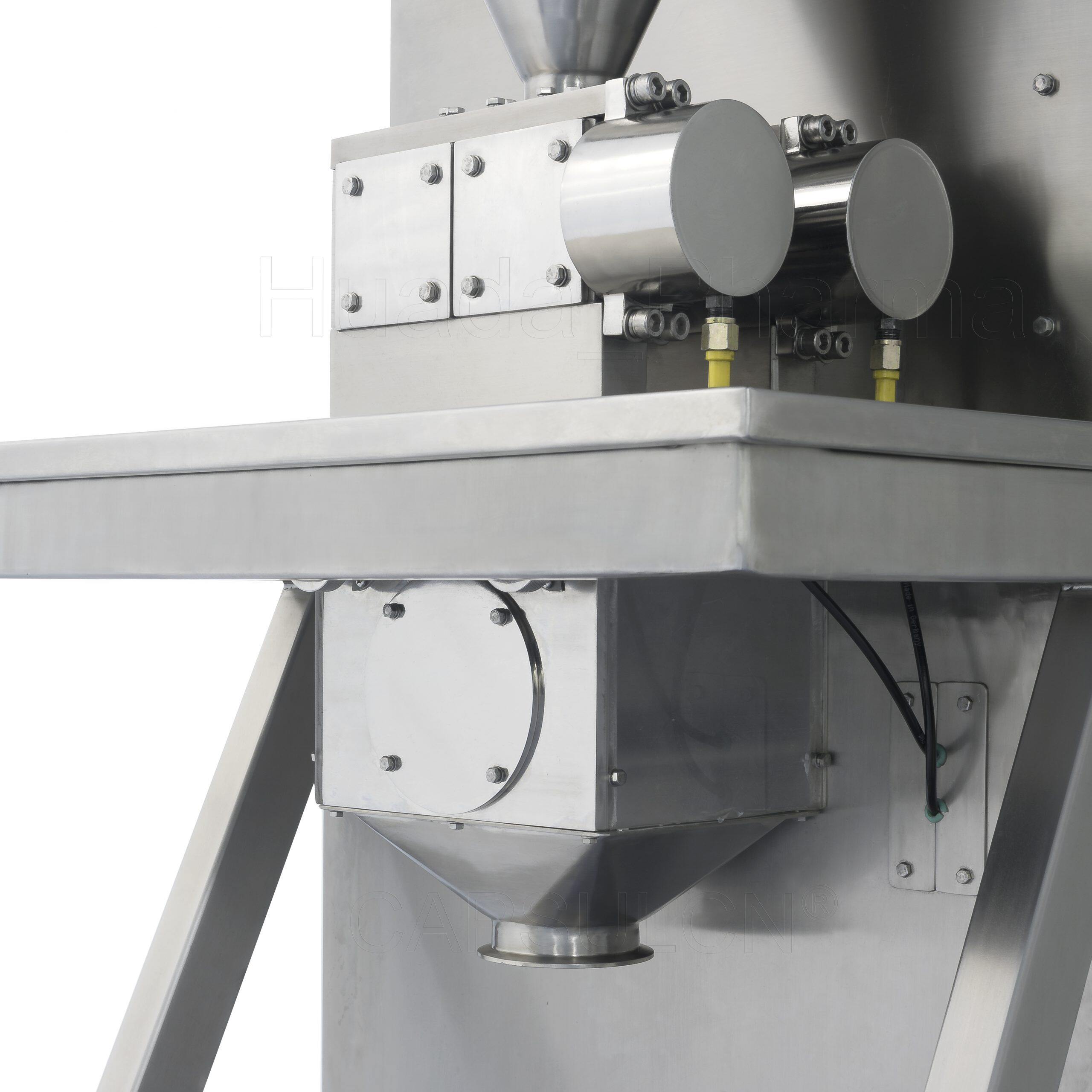

The roller compactor (granulator-compactor) uses an auger-feed system that will consistently deliver powder uniformly between two pressure rollers. The powders are compacted into a ribbon or small pellets between these rollers and milled through a low-shear mill. When the product is compacted properly, then it can be passed through a mill and final blend before tablet compression.

A Roller compactor generally consists of three major units:

- A feeding system, which conveys the powder to the compaction area between the rolls

- A compaction unit, where powder is compacted between two counter rotating rolls to a ribbon by applying a force

- A size reduction unit, for milling the ribbons to the desired particle size.

Remarks

- Dry granulators eliminate the addition of moisture and heat.

- The roller compactor is suitable for hard continuous operation as well as batch production.

- Low running cost/low operating cost and highly efficient process.

- It requires minimal floor space.

| Model | RawCN-Gra D10 | RawCN-Gra D100 |

| Capacity (kg/h) | 1 -10 | 50-100 |

| Granularity (mm) | 0.2-2 | 0.2-2 |

| Roller Size (mm) | φ100*35 | φ180*60 |

| Maximal Pressure Force (Bar) | 120 | 120 |

| Screw Feeder Rotating Speed (Rpm) | 10-60 | 20-120 |

| Maximal Granulating Rotating Speed (Rpm) | 200 | 200 |

| Maximal Roller Speed (Rpm) | 10 | 16 |

| Power (KW) | 3 | 8 |

| Weight (KG) | 350 | 1500 |

| Dimensions L*W*H (mm) | 760*800*1650 | 1500*1100*1980 |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China