TabCN-26-32-40 Pro Tablet Press

Tablet Press TabCN-26-32-40 Pro

TabCN series fully automatic high-speed rotary tablet pressing machine is the latest second generation products by our company. It concentrates on the technical characteristics of the domestic fully automatic high-speed rotary tablet pressing machine, and makes great improvements in machine structure and operation control.The structure of machine takes a universal seat, a universal shape, and a replaceable punch body, thus enabling the interchange of multiple models of the machine. The operation control adopts the industrial PLC automatic control, leaving a large development space, which can be compatible with the new products of the subsequent push (quick replacement of the disc body and other characteristics).

Main application:This machine is a single-press/doule-press type, continuous automatic tablet press for pressing granular raw materials into tablets. It is mainly used in pharmaceutical industry and also the chemical, food, electronic, plastic and metallurgical industries.

Introduction

TabCN series high-speed rotary tablet press mainly is used in pharmaceutical industries, it can also be used in chemical, food, electronic and house wares industries. It is a facility that presses various particle materials into tablet. It can also be used to produce various tablets with exceptional figures, graphs, and tablets with letters on both sides etc.These machines are suitable for producing round and exceptional tablets in large scale like medicines, sweets, calcium etc

It is a continuous automatic tablet press which can be used in the pharmaceutical, chemical, food, and electronic industries.

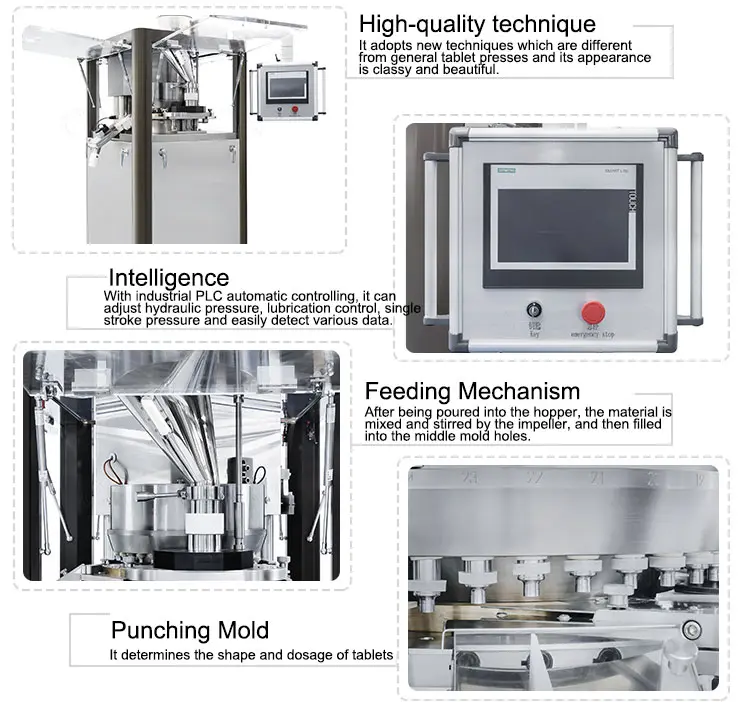

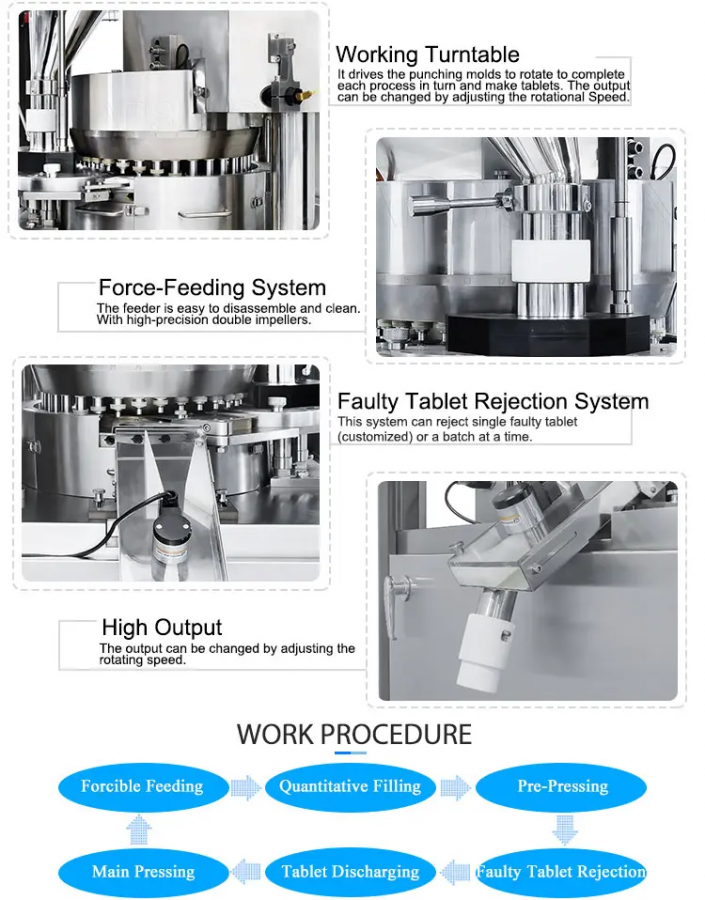

Details Images

Remarks

- The main components of the electric control cabinet adopt international famous brand components, PLC adopts Siemens products, and the human-machine interface adopts Siemens 10-inch series color touch screen.

- Low-voltage electrical products use ABB, Schneider, OMRON and other internationally renowned brand products

- Frequency converter adopts Siemens brand.

- The punching plate is processed with corrosion-resistant materials and has good rust and corrosion resistance.

- The mold damage of the tablet press and the supply of the powder are monitored to provide a safety protection. Greatly reduce production costs, improve the pass rate of tablets, and achieve one-person multi-machine management.

- Meet GMP requirements;

- The frameless large window is fitted with 20mm thick safety glass;

- Single-chip press;

- Unilateral discharge;

- Feeding motor frequency control;

- Automatic control of sheet weight;

- Remove single and multiple pieces;

- Overload, overshoot, insufficient lubrication protection;

- Suitable for round, shaped film production

| Model | TabCN-40 Pro | TabCN-32 Pro | TabCN-26 Pro | |

| No of station | 40 | 32 | 26 | |

| Capacity | Max | 260000 tablets/h | 210000 tablets/h | 160000 tablets/h |

| Min | 30000 tablets/h | 30000 tablets/h | 30000 tablets/h | |

| Rotation speed | Max | 105rps/min | 105rps/min | 102rps/min |

| Min | 11rps/min | 11rps/min | 11rps/min | |

| Max. tablet diameter | Φ13 | Φ16 | Φ25 | |

| Main pressure | 80KN | 80KN | 100KN | |

| Pre-pressure | 20KN | 20KN | 20KN | |

| Max. filling depth | 16mm | 16mm | 20mm | |

| Dia. of die | 24.01mm | 30.16mm | 38.1mm | |

| Length of punch | 133.6mm | 133.6mm | 133.6mm | |

| Main motor power | 7.5KW | 7.5KW | 11KW | |

| Dimension | 800(+440)×890(+440)×1945mm | |||

| Net weight | 1400kg | 1400kg | 1400kg | |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China